Dwight Elvey

Veteran Member

Hi Dave

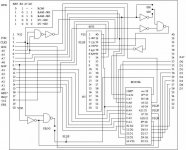

It is funny that I'd originally bought a 74138 with intentions

of using that. When I started the drawing I couldn't recall why I'd

bought it.

I still need an inverter for the R/W on the EEPROM or I'll not be able

to do in place programming. I'd really like to keep that.

I just realized that K6/7 is OK for reading but needs CLK2 for writes.

I have some cleanup to do.

Dwight

It is funny that I'd originally bought a 74138 with intentions

of using that. When I started the drawing I couldn't recall why I'd

bought it.

I still need an inverter for the R/W on the EEPROM or I'll not be able

to do in place programming. I'd really like to keep that.

I just realized that K6/7 is OK for reading but needs CLK2 for writes.

I have some cleanup to do.

Dwight

Last edited: