Unfortunately there is a lot of nonsense on the internet about doing things like re-capping VDU's and other things like discharging the CRT, when it is unnecessary and can lead to a lot of trouble.

On the capacitor issue, generally most radial electros are pretty long lasting unless near heat sinks, especially ones in signal circuits. The only electros that should be targeted for replacements are the surface mount parts as they are terrible and leak, dry out or both. Or perhaps a capacitor which fails an in circuit ESR test or is obviously in trouble with a domed top.

In any case, onto the topic of CRT discharges, or discharges that can occur from the CRT's anode connection to ground, either naturally with contamination around the EHT cap, or if the EHT peaks too high, or deliberately when a person shorts out the stored charge in the CRT bulb. It is a recipe for disaster.

(from the safety perspective it is not required unless the anode cap needs removing, typically to replace the CRT or remove the flyback, for most VDU's, provided the access is reasonable, the cap is better left connected, the stored charge is safely inside the CRT bulb, it cannot escape unless you go under the cap. If it is to be discharged, it should be done with an EHT probe which contains a very high value resistor, with a high voltage withstand spec, typically these resistors, inside the probe, are in the 100M to 1G Ohms, this limits the initial discharge current to a low value)

The CRT bulb's internal and external Aquadag forms the plates of a capacitor and the CRT bulb glass the dielectric. For a CRT of this size the capacitance can be in the range of 2000pF at least. When charged to the order of 21kV or thereabouts the stored energy is in the order of (CV^2/2) or 0.44 Joules. That is not enough to harm a person with a shock, only enough for a significant fright. However a discharge (either intentional or accidental, even to some random earth point) can do substantial damage to semiconductor devices in the set.

If a 2000pF capacitor (which is what the CRT bulb is) charged to 21kV is shorted out with a wire, the initial peak current is horrific. It is only limited by the inductance of the wire, its resistance and the the spark plasma. The spark occurs before the wire touches the discharge point, because the spark gap firing distance in free air is typically around 1000v/mm, so the spark will jump at easily over 1cm for 20kV. The spark plasma as an electrical entity, tends to drop a constant voltage of around 500V in air and has a negative resistance. So as the current increases the plasma gets thicker. The net effect is that the spark itself doesn't help limit the initial peak discharge current of many thousands of amps. If the CRT gets discharged with a wire, depending on the chosen earth point, or even to the CRT's external Aquadag, there is a large current impulse injected into the earthing system, often into the the pcb tracks and components.

This is why , if a CRT is to be discharged, it should be done with the EHT voltage probe with at least 100M Ohms resistance, to limit the initial discharge current to say 21000/100,000,000 or about 0.2 mA.

In the early days, of tube TV's technicians would draw an arc from the EHT with the set running and judge the length of it, the EHT value. When this was tried in transistor sets, many of the transistors died. It prompted Sony, in about 1962, to advise not to allow arcs in transistor sets from the EHT terminal. It seems though that later generations of technicians who like to make youtube videos know nothing about this problem.

I think in this case, either the turn on voltage crack you heard, or perhaps if you discharged the CRT with a wire, (or maybe you had a very large value high voltage rated resistor, like ones in EHT probes) I'm not sure if you did, but this direct short is also what the many defective youtube videos suggest along with global recapping, has likely been responsible for some semiconductor damage in the set, though there could be other causes.

After all that, what about your set now and what does the video show and what can we do about it?

The video shows that the H and V scan starts up, and is running long enough to power the CRT's EHT and run it briefly. Then the H scan shuts down. (While it could be the main psu shutting down, it looks less likely because there was a full H scan shut down but the vertical scan momentarily at least remained preserved).

In any set where the EHT runs over around 17kV, there is always the opportunity for X-ray production as the electron energy becomes high enough. In color TV's and VDU's which run the EHT In the range of 20 to 25kV there is normally an EHT over-voltage detection circuit, or at least a feedback control circuit to regulate the EHT, to protect from excessive X-Ray production. Pin 9 on the HA11235 IC is the X-ray protector input pin, driven by the OP amp.

When the EHT gets excessive, it shuts down the drive to the H scan circuitry. I think this is what is happening after you power it up. The fact that you also initially heard a discharge (crack) suggests that possibly the EHT had climbed higher than normal value too.

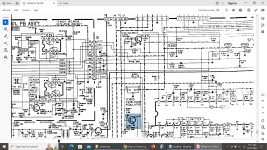

What I would suggest is checking your re-capping work in the region of the OP amp that detects the EHT value (see attached). It could also be that the discharge/s damaged the OP amp and it may require replacing.

(I'm not sure how much disassembly you did, to do the re-cap, but check the earth connection to the CRT's external Aquadag too, for example if that gets disconnected and the CRT discharges a plasma can jump from that onto some nearby pcb location also check that the earth wire exiting the EHT multiplier/focus & screen voltage assembly is properly connected)

drive.google.com

drive.google.com

drive.google.com

drive.google.com