Hugo Holden

Veteran Member

This makes much more sense to the layperson.

If that resistor on the yoke is R403 no wonder I couldn't find it. I was looking on the pcb. Its resistance = 4.2ohms. I also saw the number 1 and 2 on the white piece of plastic. NOW it makes sense. ;-)

Pin 2 = 14.47v

Pin 5 = 13.92v

If waveforms are next and Hugo assists in me finding a decent, not too expensive scope what exactly will the waveforms diagnose? Does this mean cutting the glue on the yoke against the tube, adjust the yoke and then re-glue it with the power turn on? I do have electrical insulated rubber gloves but never used them!!! ;-)

Don't do things like cutting glue and removing the yoke.

What you are interested in is to confirm that the DC resistance of the V yoke coil combination closely matches that of other 5151 VDU's, which you have done and got 4.2 Ohms,so forget about the yoke being the problem for now, and concentrate on why, as the scan progresses the current is not rising at the rate that it should toward the bottom of the raster screen.

I mentioned the possible causes.

(A yoke with shorted turns in one of the two windings would be expected to have a lower DC resistance than normal and if one of the two windings was open circuit, since they are in parallel, one would expect the DC resistance to be double that of the standard value, so it looks the the yoke is out of the equation).

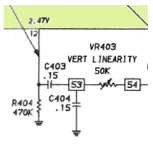

A high resistance connection in the wiring leading to the yoke (double check the DC resistances). A High ESR or wrong value yoke coupling capacitor could do it. Are you sure this replacement capacitor is suitable ?

Now we know the IC is ok, and the power output stage in the IC is ok (remember I suspected it was because the DC voltage on the output was about right), there are really only two other possibilities. One is that the power supply to the IC is sagging down during the V scan, you could see that on a scope, but probably not wonderfully likely with the meter voltages you have measured.

The other is, that the output stage of the IC is being presented with an incorrectly shaped drive waveform (the output amplifier in the IC can only reproduce the drive wave it is being fed with), and what you are seeing on the screen is simply a manifestation of that . The drive wave is supposed to be basically sawtooth looking. This is where the scope comes in handy, comparing the waves with what is shown on the previous documentation and also checking the dynamic stability of the power supply voltage. To do this latter test the scope must be set on DC coupling.

Last edited: