pjhacnau

Experienced Member

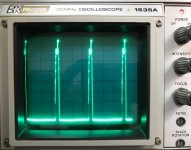

Looks like the vintage of your scope matches the vintage of the machine

Looks like the vintage of your scope matches the vintage of the machine

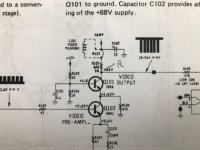

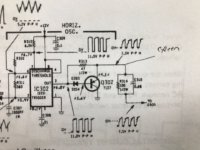

Power supply caps changed and Motorola video flyback transformer repaired...

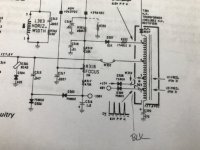

View attachment 52563 View attachment 52564

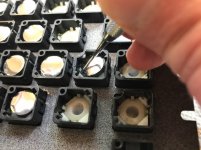

Superglued the ferrite back together:

View attachment 52565

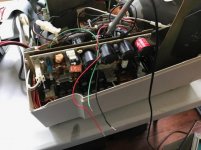

Now to replace it:

View attachment 52566

If you look at the tip of the screwdriver in this photo, there's a nut underneath that the brass rod screws into. Once the solder repair is done I tightened the nut to hold the ferrite securely, but not too securely..

View attachment 52567 View attachment 52568

I didn't get too wrapped up in making it fit like when it was new, only that it was all in place and secure. Also, didn't want to use too much heat around the ferrite.

Awsome work, I just scored a free Model 16 as well, Can't wait to start using it.

That looks very useful. Could it also be used with a 12/16B/6000 if a proper cable was made?

Great thread. I restored a 16A last summer and had a great time with it. Have a Model II with a bad 68000 card I need to figure out now, your thread has me planning to start back this weekend.