80186 Enthusiast

Experienced Member

- Joined

- May 18, 2023

- Messages

- 53

WARNING: Lots of text and images!

Hello. I've spent some time making changes to the schematic and creating a PCB based off of the new schematic. The SeaOtter Essentials Prototyping Computer V1.2 (design) is here!

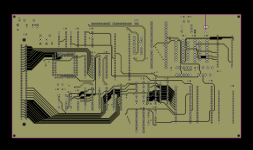

Schematic:

any part labeled "74LS" is actually a 74ACT series chips. same goes for the PCB layers below!

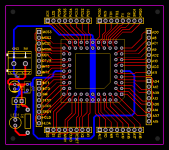

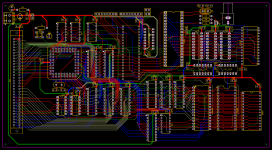

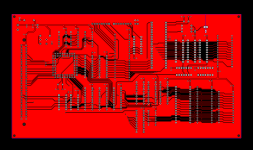

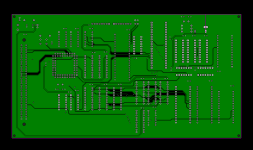

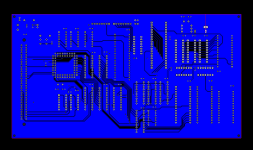

PCB Layers:

I've added Grounding Vias to the PCB design after creating these PCB Layer renders.

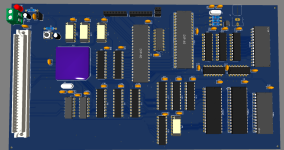

3D Screenshot:

I've watched a YouTube Video about Traces in a PCB Design and I learned that in digital electronics, Traces that carry data signals need to be as short and as straight forward as possible and need a little space between each trace to avoid crosstalk (The electromagnetic field of a PCB trace affecting other traces). However, the Video said I should worry about cross talk if my design is running at High Frequencies ... the CPU's fastest speed is 12Mhz. However, I didn't hear about the warning for cross talk only being a problem for high frequency. So for a little bit, while designing the PCB. I was trying to make the traces as short and as straight as possible and I stopped the moment I heard the warning for crosstalk only being a problem for high-frequency electronics. However, There still is a need to keep the traces as short as they can be... I've double checked my traces a few times (At least to me) most of the traces look decent in terms of distance. I also learned that traces with too many bends can cause data signal delays, but again I should only worry about that if my design is a High frequency design.

With that mild panic out of the way, I am very proud of my design here. to me, it looks and feels like a motherboard that would be in a home-computer (A computer that has a built-in keyboard and monitor). Speaking of which ... I never was very clear about the kind of computer I am creating here. As already stated, it'll have a built in keyboard and monitor, like a commodore pet or a Sharp MZ-80 computer. I want the motherboard to have everything integrated onto it. The purpose of the expansion slot is to add the next I/O components, which are a Serial Controller and a I/O Controller with an SD Card Interface to be added to the next prototype design. The expansion Slot will also be used for seeing which CPU pins need to be grounded or pulled up to 5v by using Pin Headers and jumper cables or DIP Switches. I know that the CPU should work just fine, but to my understanding having some specific pins on the CPU float can cause some performance hits. Let me know if I obsoletely need to have some pins pulled down to GND or 5v like what's seen in the 80186 Data sheet (Images below) in the replies to this post.

Having A bus transceiver to act as a Buffer for I/O and Memory is directly based off of how the Tandy 1000 did the same thing. The DIR Pins on those transceivers connected to the I/O or Memory Read signal (basically, when that pin is LOW, Data flows from side B to A and when that pin is HIGH, Data flows from side A to B). The output enable is tied to the I/O or Memory Chip Select signals, which is similar to what it is on the Tandy 1000. The biggest Difference is the I/O and Memory Select Signals comes from the CPU directly instead of external chip-select logic.

Going back to the home-computer design for a moment. For the built in monitor, I've found this "Television" on Adafruit's website and while the screen size is only 3 inches long, its a suitable temporary solution until I find something that's similar but bigger.

I'm considering adding 8-Bit ISA slots because previous replies told me I could drive ISA Expansion cards due to I/O Read and Write signals, but I might just save that for experimentation later on in this project's life.

One last thing I have for this post is just a simple question. Is this 8 MHz Crystal from Digikey suitable for proving the x1 and x2 clock input pins for the N80C188-12?

As always, if there is anything I've done wrong or if there is anything I need to fix with either the schematic or PCB design, please let me know in the replies below!