Dear Forum Members,

This is a continuation post regarding my previous post about the required dummy load resistor.

With my dummy load resistor, I am still getting the same in-circuit measured results when trouble shooting (PDF page 31, 2-1 THE SWITCHING REGULATOR UNIT FAILURE) as without any load.

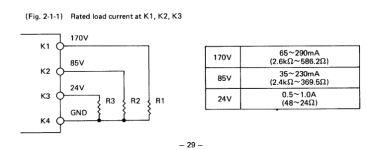

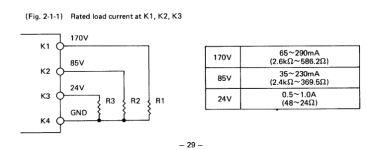

Here's the specs for the required resistor network from the service manual:

My dummy load resistor is

K1 -> K4: AX9W 820R + AX9W 820R

K2 -> K4: ROYAL 162 P 5W 2K2 J

K3 -> K4: 10W22OhmJ + 10W22OhmJ

With the dummy load resistor connected to, the measured resistances are

K1 -> K4: 1.558k

K2 -> K4: 2k

K3 -> K4: 44 Ohm

and for comparison, with the MAIN PWB connected:

K1 -> K4: 47.8k

K2 -> K4: 46.1k

K3 -> K4: 879 Ohm

and here's a recap of some in-circuit, trouble shooting flow related measurements:

This is a continuation post regarding my previous post about the required dummy load resistor.

With my dummy load resistor, I am still getting the same in-circuit measured results when trouble shooting (PDF page 31, 2-1 THE SWITCHING REGULATOR UNIT FAILURE) as without any load.

Here's the specs for the required resistor network from the service manual:

My dummy load resistor is

K1 -> K4: AX9W 820R + AX9W 820R

K2 -> K4: ROYAL 162 P 5W 2K2 J

K3 -> K4: 10W22OhmJ + 10W22OhmJ

With the dummy load resistor connected to, the measured resistances are

K1 -> K4: 1.558k

K2 -> K4: 2k

K3 -> K4: 44 Ohm

and for comparison, with the MAIN PWB connected:

K1 -> K4: 47.8k

K2 -> K4: 46.1k

K3 -> K4: 879 Ohm

and here's a recap of some in-circuit, trouble shooting flow related measurements:

- 0V across any combination between K4-K1

- Steady +17V across pins 13 and 16 of IC601.

- Voltage across + and - terminals of D601 is +325V (no mention in the service manual what this should be, with my input 230VAC this is OK? RMS?)

- R603 should be OK (~68k in-circuit)

- R630 should be OK (~47k in-circuit)

- R610 should be OK (~0.4 in-circuit)

- R616 and R617 should be OK (6.9 in-circuit)

- Fuse F601 is OK.

- R624 should be OK (~69 in-circuit)

- R627 should be OK (2,2 in circuit)

- R601 should be OK (~15 in-circuit)