Mike_Z

Veteran Member

Well..... spent the last couple of days, cleaning and removing the corrosion from the front panel control board. Been using alcohol, vinegar, cotton swabs, old toothbrush and small paint brush. The alcohol does a good job on the oil removal and the vinegar helps with the corrosion. Inspection found a couple broken resistors, two frozen switches and a few suspect lamps. I loosened up the switches, but they do not make up. I may try and remove one of them later to see if I can open it up and make a repair.

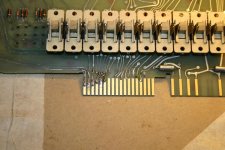

Next I removed, photographed and labeled the cards. One item is that the card space is divided into two areas. The front has a 20 space omnibus with all the DEC cards in place. The back is a different motherboard. It is made by Kearney and Trecker, here in Milwaukee. My Father-in-law worked there before and after the War. This back mother board has 15 KT boards in it and physically connects with two heavy ribbon cables to the M863 12 channel I/O board. One thing that puzzles me is how all this stuff connected to the machine tool. I didn't remove the unit and was not there when it happened. There are a few empty sockets which could have been used to connect to the machine tool, but how did the wiring come out. Usually there are a bunch of terminal strips for external wiring. Something to find out, when I go back to the machine shop and talk to my friend.

I want to remove the two motherboards and clean them. They are oil covered and the omnibus has corrosion on the first two slots. There seems to be a handful of metal chips in the case also. So a good cleaning is needed, Then on to the power supply. Another odd thing is the power supply connection cables are rather hard, very inflexible AND the wire size is small. I saw on one of the power supply prints, the +5 can supply 20 Amperes. The wire looks no larger than a #18 wire. The plugs and sockets are also beat up some. Maybe some of this will be changed out also.

Mike

Next I removed, photographed and labeled the cards. One item is that the card space is divided into two areas. The front has a 20 space omnibus with all the DEC cards in place. The back is a different motherboard. It is made by Kearney and Trecker, here in Milwaukee. My Father-in-law worked there before and after the War. This back mother board has 15 KT boards in it and physically connects with two heavy ribbon cables to the M863 12 channel I/O board. One thing that puzzles me is how all this stuff connected to the machine tool. I didn't remove the unit and was not there when it happened. There are a few empty sockets which could have been used to connect to the machine tool, but how did the wiring come out. Usually there are a bunch of terminal strips for external wiring. Something to find out, when I go back to the machine shop and talk to my friend.

I want to remove the two motherboards and clean them. They are oil covered and the omnibus has corrosion on the first two slots. There seems to be a handful of metal chips in the case also. So a good cleaning is needed, Then on to the power supply. Another odd thing is the power supply connection cables are rather hard, very inflexible AND the wire size is small. I saw on one of the power supply prints, the +5 can supply 20 Amperes. The wire looks no larger than a #18 wire. The plugs and sockets are also beat up some. Maybe some of this will be changed out also.

Mike

![IMG_0240[1].jpg IMG_0240[1].jpg](https://forum.vcfed.org/data/attachments/20/20935-ef702c760485e843143ca3c1a121b75b.jpg)

![IMG_0241[1].jpg IMG_0241[1].jpg](https://forum.vcfed.org/data/attachments/20/20936-8267cdfd879167a445e3a04259900333.jpg)