haglebu

Experienced Member

Both computers basically use hard-sectored floppy disks with 10 sectors in 5.25" format. Both FM and MFM, single-sided and double-sided are possible.

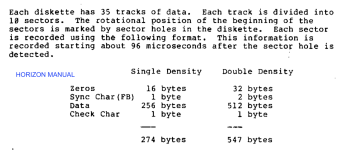

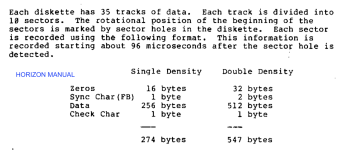

To the Horizon format I have read (I do not know however where) that here NO track and/or sector ID is used. In the Horizon manual is only talk about 96 microseconds between sector hole and start of DATA. Therefore the drives must be really optimal set for 300 RPM.

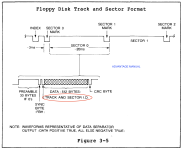

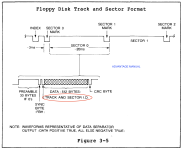

In the Advantage manual, however, I found information about the sector and track ID between SYNC BYTE and DATA.

Does anyone have further or more in-depth information on this?

To the Horizon format I have read (I do not know however where) that here NO track and/or sector ID is used. In the Horizon manual is only talk about 96 microseconds between sector hole and start of DATA. Therefore the drives must be really optimal set for 300 RPM.

In the Advantage manual, however, I found information about the sector and track ID between SYNC BYTE and DATA.

Does anyone have further or more in-depth information on this?

Last edited: