thunter0512

Veteran Member

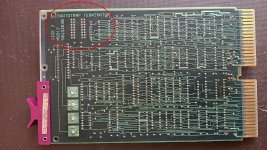

I am restoring a PDP-11/34 in what I think is a BA11-K box and found the 11/34 related manuals & drawings on Bitsavers.

While restoring my LAB-8/e and PDP-8/e I found the 8/e maintenance manuals with detailed theory of operation very useful.

I could not find the same level of detail for the 11/34. Do such documents exist for the 11/34.

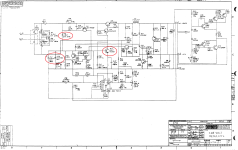

Specifically other than schematics I found nothing about the power supply modules H744 (5V 25A), H745 (-15V 10A) and H754 (20V 8A, -5V 1A).

Questions:

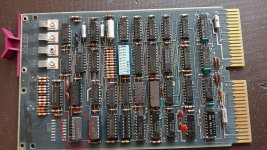

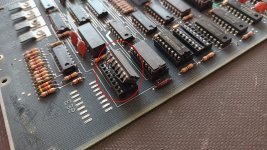

My plan is to get all power supply rails stable and then start debugging the M7265/M7266 CPU boards and KY11-LB programmer's console.

I expect a steep learning curve as I have never even seen any PDP-11 before.

While restoring my LAB-8/e and PDP-8/e I found the 8/e maintenance manuals with detailed theory of operation very useful.

I could not find the same level of detail for the 11/34. Do such documents exist for the 11/34.

Specifically other than schematics I found nothing about the power supply modules H744 (5V 25A), H745 (-15V 10A) and H754 (20V 8A, -5V 1A).

Questions:

- Are there documents which describe the "theory of operation" of the H744, H745 and H744 power supply modules.

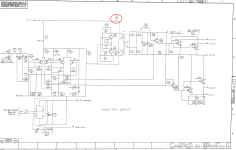

- Are there better schematics of these power supply modules than found in "MP00082_1134_Vol2_Sep76.pdf" from Bitsavers with the title "11/34 Vol 2 Field Maintenance Print Set".

My plan is to get all power supply rails stable and then start debugging the M7265/M7266 CPU boards and KY11-LB programmer's console.

I expect a steep learning curve as I have never even seen any PDP-11 before.