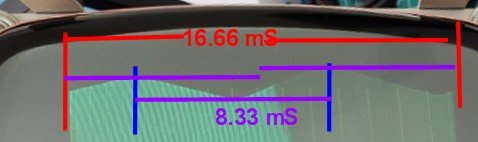

...just to double check something, those waves modulating the width of the scan, since we have a photo and not a video, are floating or drifting down the sides of it ? or are they stationary ?

(Q721 acts as a switch and is switched on for about 2/3 of the H scan time and switched off at the right had side of the scan line. When it is off, the CRT beam flies back to the left hand side to start the scan line again and about 1/3 to 1/2 of the scan on the left side is done by damped current via D721, rather than Q721's collector current. Since the width of the horizontal scan line is being modulated by 120Hz ripple, currently we are assuming somehow this is getting past the regulator and modulating the 18V supply feeding the H output transformer and Q721)

It is hard to think that TP1 has close to 18V DC on it and it is free of ripple. Since the H scan width is reduced as well as being modulated by ripple voltage. By the look of the width of the scan I would guess that there is more like 15V or 16V DC on TP1 with at least one volt of ripple superimposed there.

The reason is that the transistor Q721 is a saturated switch (if not it overheats very quickly). The scan width is determined by the time that Q721 is switched on per cycle. This drive signal ultimately comes from the computer as the H drive signal. Once Q721 is switch on, the current rizes at a high rate of V/L Amps per second (but Q721 is not switched on very long per cycle, the peak current at the left side of the scan would be around 2.5 to 3A), where V is the 18v power supply voltage and the L inductance of the yoke's H coils & transformer combination. Since the inductances are a constant, it is the supply voltage V that can modulate the H scan width.

There could possibly be other causes of ripple modulating the H scan width, other than full wave ripple from the line supply, but there are no components there which could easily create a low frequency resonance of about 120Hz and it would seem to be a big coincidence that the ripple frequency seems to exactly match twice the line frequency, which is the type of ripple out of a full wave rectifier system.

The line power frequency of course is not exactly synchronized with the PET's vertical scan frequency, so, if the ripple modulating the width of you H scan is coming from the line power source somehow via the regulator IC, in theory then, it should be crawling down the sides of the scan and not stationary, which is why I asked the question. If the waves are perfectly stationary compared to the scan, then we need to put on our thinking caps.

Please double check that the correct transformer connections are feeding the VDU and double check the AC voltage, that the transformer is sending to the VDU at the input to the bridge rectifier. Obviously, if the AC output voltage of the transformer was too low, 120Hz ripple would break through the regulator, but, since you have changed that transformer already, that doesn't seem likely, unless something else connected to the transformer is overloading it, affecting the output of both transformers you have tried, could be a plausible explanation. As Daver2 pointed out 10V AC is way too low and at best could only generate 14V across C901, a little less too, due to the 1.2v forward voltage drop of the bridge rectifier. Almost like the AC voltage is getting close to about 1/2 what it should be.

You don't have a 230V PET running on 115V by mistake do you ? Check the transformer connections. But that seems unlikely because you said it was working before it suddenly failed. In the case of dual voltage transformers they have two primary windings, placed in series for 230V and parallel for 115V. In this latter case of one of the primaries goes open (or not wired correctly), the transformer cannot source the normal amount of current without its output voltage sagging down.

Just maybe your first transformer was a 115V version and it failed. But the second one you tried producing the raster with ripple was a 230V version. Just something else to check on.

(C902 has to be in good order for the voltage regulator to be stable, worth double checking)