MattisLind

Veteran Member

This has been discussed before I think.

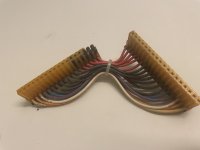

Opened up a VAXstation II/GPX in BA23 and the power harness wasn’t happy at all. In the previous BA23 I worked the power harness had white connectors and was in perfect shape.

So what should I do to replace it so it won’t catch fire? What is the proper connector. Some Molex KK 396 connector?

Opened up a VAXstation II/GPX in BA23 and the power harness wasn’t happy at all. In the previous BA23 I worked the power harness had white connectors and was in perfect shape.

So what should I do to replace it so it won’t catch fire? What is the proper connector. Some Molex KK 396 connector?