iainmaoileoin

Experienced Member

I am the proud owner of an RJS03 fixed-head disk system.

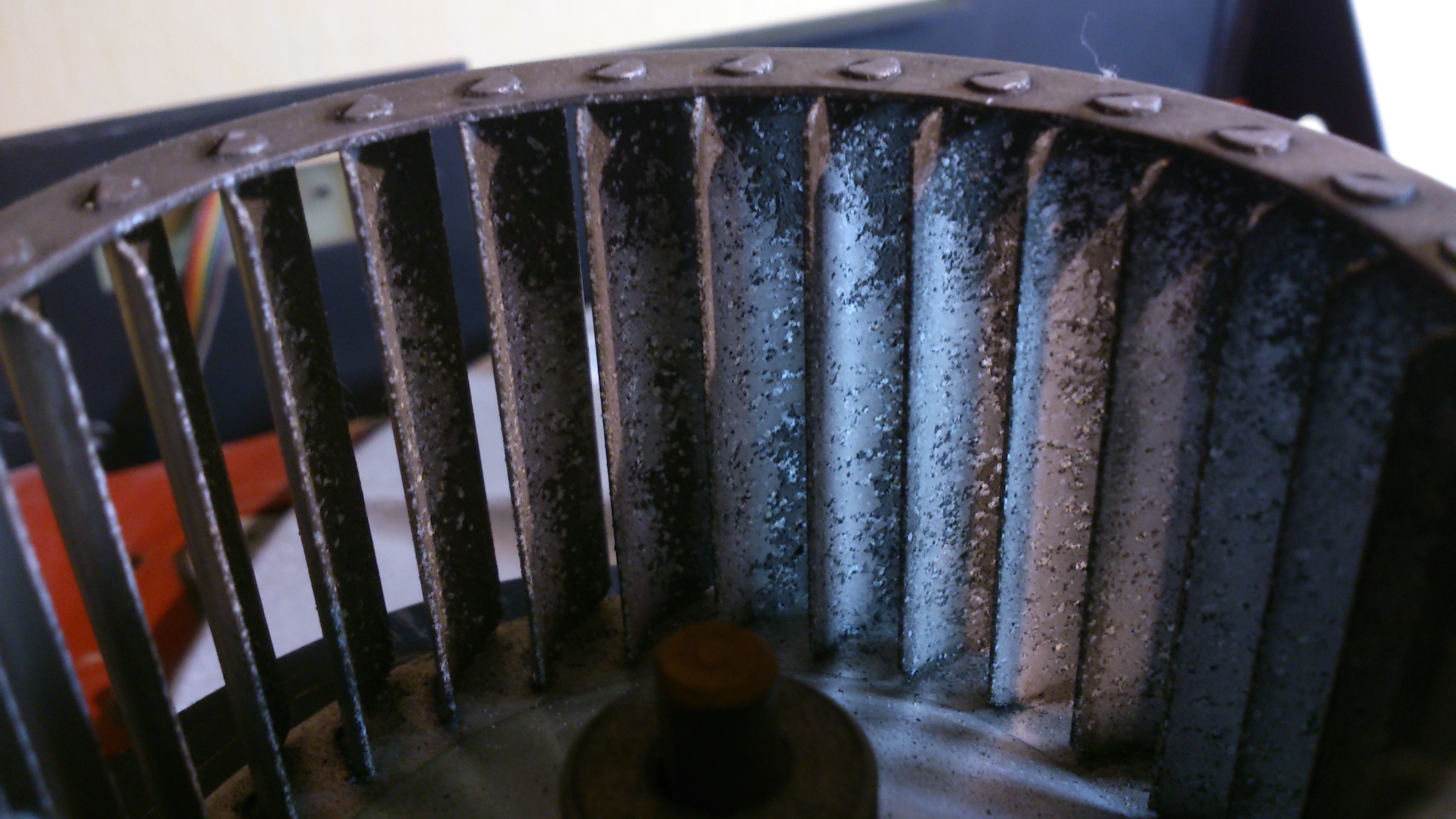

I don't have the guts to power it up yet - Scotland cant afford to lose another Hunterston reactor over the cold period

More seriously I need to strip down the boards, inspect, clean, reassemble before I go anywhere near putting power towards it.

I have no idea yet if the motor even spins up.

Does anybody have any experience of one of these drives?

Anything I should watch out for (except putting my back out) before I apply power and toast it by mistake.

Thanks in advance.

I don't have the guts to power it up yet - Scotland cant afford to lose another Hunterston reactor over the cold period

More seriously I need to strip down the boards, inspect, clean, reassemble before I go anywhere near putting power towards it.

I have no idea yet if the motor even spins up.

Does anybody have any experience of one of these drives?

Anything I should watch out for (except putting my back out) before I apply power and toast it by mistake.

Thanks in advance.