Hi all,

After about 12 months I have finally found a free day to have a look at my Olivetti M24 (AT&T 6300) colour display.

I bought the colour CRT (which is an Olivetti branded one) a while ago and only briefly tested it. At the time I noticed I couldn't adjust the brightness/contrast low enough, and you could always see the raster pattern no matter what.

Today I thought I would have another go and see if I could narrow down the problem. What I found was something I had never observed before.

When the screen is predominantly black (i.e. at the DOS prompt) you can easily adjust the brightness and contrast to the correct levels.

As soon as the screen begins to fill with an image (irrespective of colour) the brightness 'ramps up' across the whole display. The ramping is almost like a capacitor charging, the image appears perfect for about a second then you see the brightness 'ramp up' over the course of another 1-2 seconds. Depending on how much of the display is filled, the brightness increases in proportion. If enough of the display is filled, its so bright that the raster is clearly visible. I have attached a few images for reference.

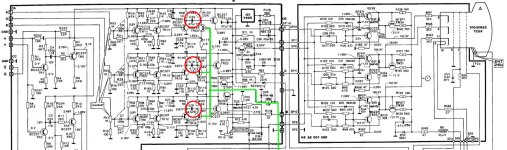

Before I rip into the display and blindly look for faults, any pointers on what could cause this behavior? Unfortunately I don't have any circuit diagrams for this particular model; it's different from the AT&T counterpart and no matter how much I have searched I come up empty.

Thanks for the help!

After about 12 months I have finally found a free day to have a look at my Olivetti M24 (AT&T 6300) colour display.

I bought the colour CRT (which is an Olivetti branded one) a while ago and only briefly tested it. At the time I noticed I couldn't adjust the brightness/contrast low enough, and you could always see the raster pattern no matter what.

Today I thought I would have another go and see if I could narrow down the problem. What I found was something I had never observed before.

When the screen is predominantly black (i.e. at the DOS prompt) you can easily adjust the brightness and contrast to the correct levels.

As soon as the screen begins to fill with an image (irrespective of colour) the brightness 'ramps up' across the whole display. The ramping is almost like a capacitor charging, the image appears perfect for about a second then you see the brightness 'ramp up' over the course of another 1-2 seconds. Depending on how much of the display is filled, the brightness increases in proportion. If enough of the display is filled, its so bright that the raster is clearly visible. I have attached a few images for reference.

Before I rip into the display and blindly look for faults, any pointers on what could cause this behavior? Unfortunately I don't have any circuit diagrams for this particular model; it's different from the AT&T counterpart and no matter how much I have searched I come up empty.

Thanks for the help!