What's the common wisdom here? While the monitor is open, should anything be replaced in a preventative way?

Not really. I cannot think of anything (perhaps aside from the electrolytics) that could be replaced in a preventative way (perhaps just one thing). Even then, it appears that most of these VDU's were originally fitted with good quality Nichicon electrolytic caps and they are generally ok.

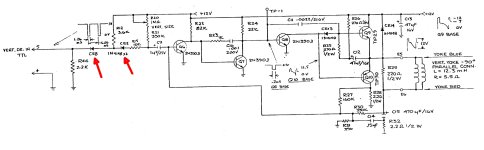

But there is the one exception, the electrolytic cap that filters the negative supply rail to the brightness control, needs to be about 10 times bigger in uF value. Oddly, it would have been about perfect, as they had it, if the brightness control pot was a 1M Ohm value (not 100k) also 1M Ohm for that part is a more typical value because a CRT's grid current is negligible. With the 100k pot they have there it is better to increase the capacitor from around 3.3uF to 330uF (or at least 220uF), otherwise, when the VDU is turned off, the high intensity beam can burn the CRT phosphor near the screen center (the old after glow spot problem of TV style CRT's).

Perhaps one other thing, in these VDU's they pushed the 12V regulator pretty hard with thermal dissipation. It manages just because of the very large heatsink it has. It is worth making sure that it is well thermally bonded to the heat sink with fresh thermal compond. If it has a screw and nut do that and securely tighten the nut. If it has a rivet, which some units had, it can be a problem as it distorts the tab on the TO-220 device and it weakens the thermal coupling to the heat sink especially if there is a paucity of thermal compound and it has dried and gone powdery.

Also the two TO-220 package vertical scan output transistors were "borderline" for requiring a heat flag on them. Some 9" VDU's have them some not. It is worth fitting those I think, I did for my 9" VDU's.

Then there are the other 4 things you could do, that are pretty optional, described in my article:

1) add the Germanium energy recovery rectifier to improve the left sided H scan linearity.

2) change the yoke coupling capacitor from 10uF to 8 or 8.2uF to improve the H scan linearity too.

3) add the zener diode to help protect the unit's horizontal output stage if the H.Drive signal from the computer goes awry.

and if you get really fanatical like me:

4) add a focus potentiometer, to gain the best compromise between corner and center focus on the CRT.