Hello, many thanks for checking... the service manual asks for a time mark generator and I don't have such a device.

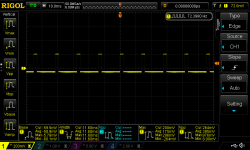

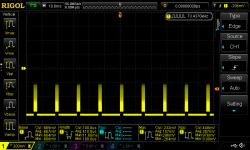

I've got a function generator, Wavetek 143, which has probably never seen a service is its life and is most likely not 0.5% accurate. Is that sufficient or do I need a time mark generator and is there a difference between that and pulse generator?

I'll be on the lookout for one and I'll try to check I can get somewhere with the old Wavetek.

I've got a function generator, Wavetek 143, which has probably never seen a service is its life and is most likely not 0.5% accurate. Is that sufficient or do I need a time mark generator and is there a difference between that and pulse generator?

I'll be on the lookout for one and I'll try to check I can get somewhere with the old Wavetek.