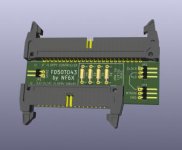

NF6X

Veteran Member

I did splice together 2 floppy cables a 50 pin to a 34 pin although I did not have much luck getting it to work the motor was off until I inserted a disk and closed the drive latch. Then the motor came on. Sounds like that is what should happen. So I think.

Sounds right.

Also even with an external drive configured as drive DS1 the system will always want to boot the internal drive no matter what. So I can't boot from the external unless I hook it up to the internal connector? Which makes sense. Then put the internal drive on the external connector? Then boot the 5.25 connected to the internal connector. And the 8" will be the external drive as DS1. The I can transfer files from the 5.25 to the 8". Or am I way off course. Let me know.

That sounds right with one addition: You'll also need to change the jumper on the internal drive from DS0 to DS1.

Mark: is the PDF schematic current? I was wanting to build an adapter according to your diagram.

I would not trust my schematic just yet. It's under active development, and I threw out that first draft for y'all to find my mistakes.