OK, here is my brain dump of gridcase 3p related stuff

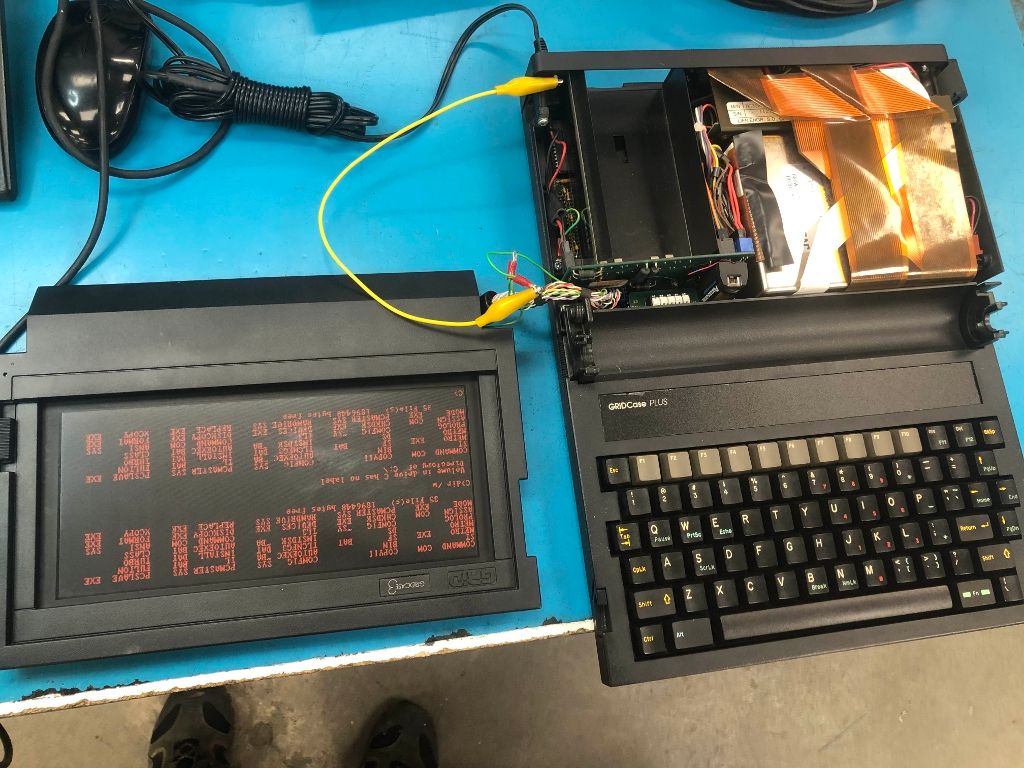

MFM controller + DREM3 PCB happy together.

View attachment 1287862

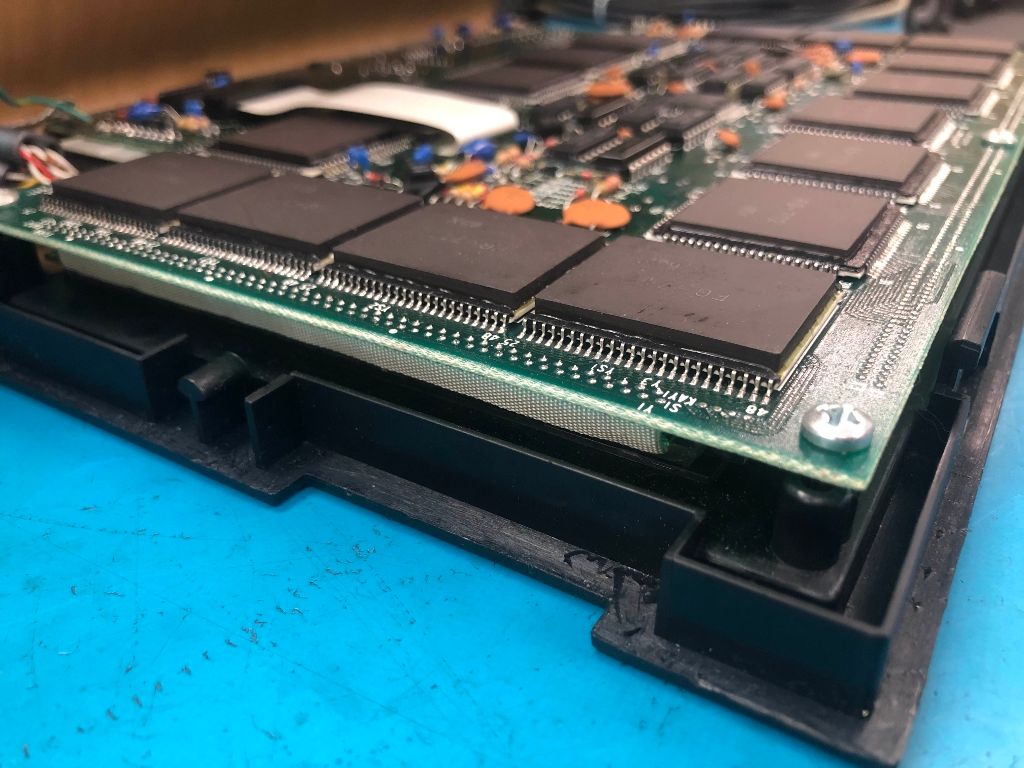

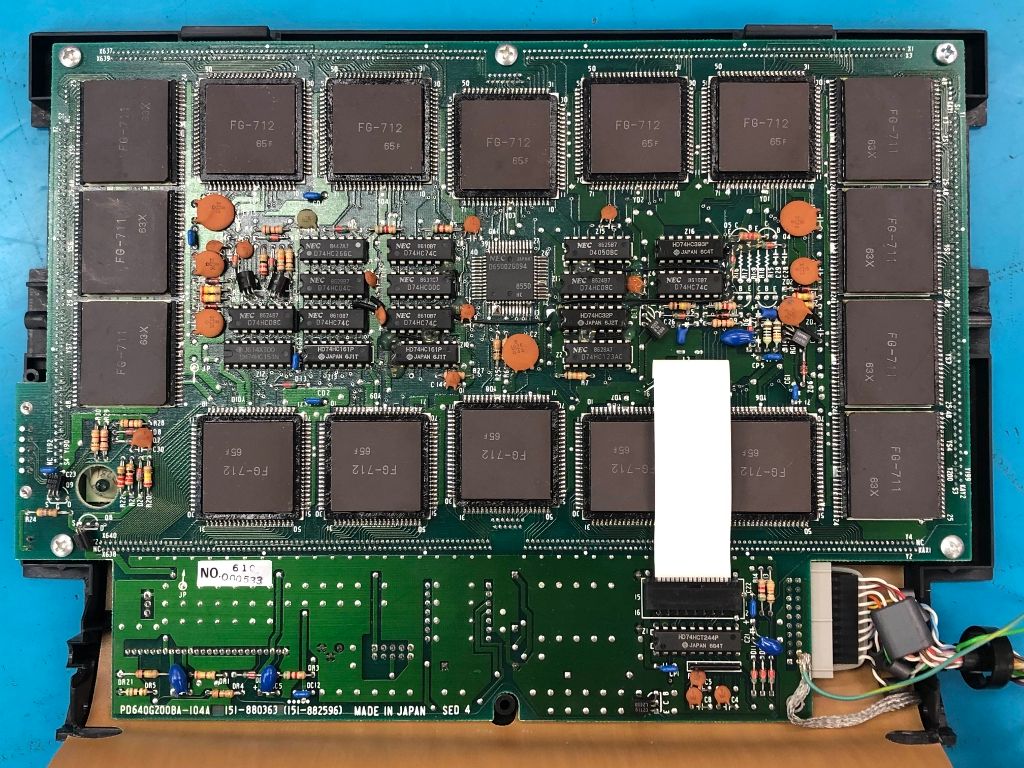

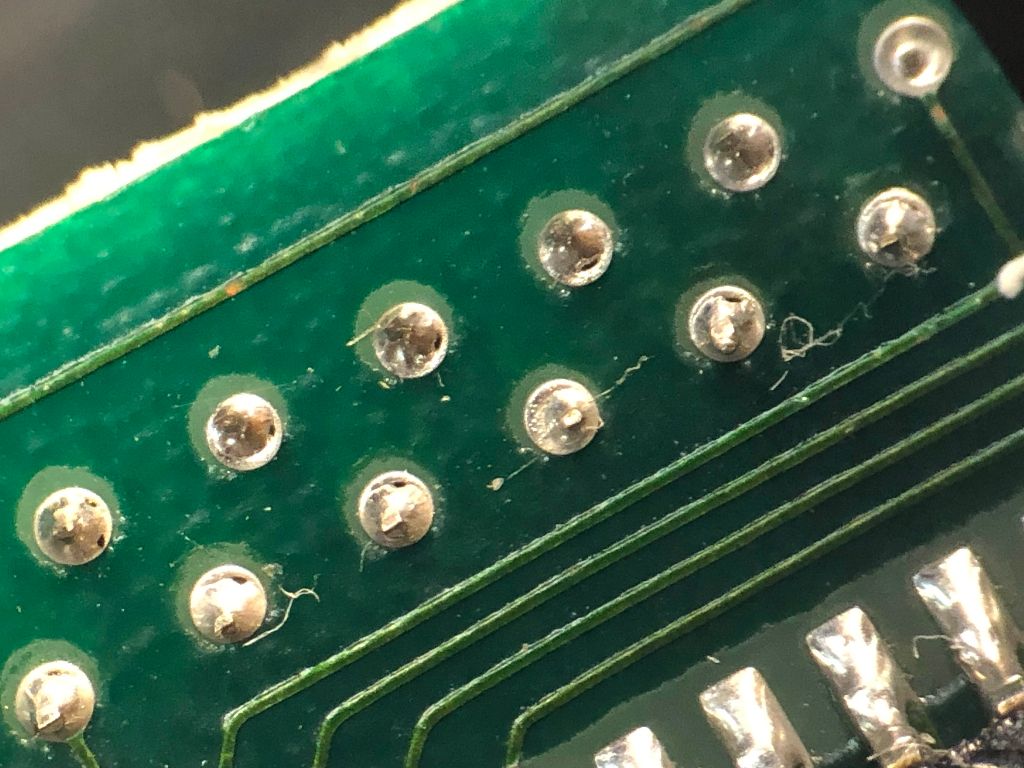

bottom of MFM controller

View attachment 1287863

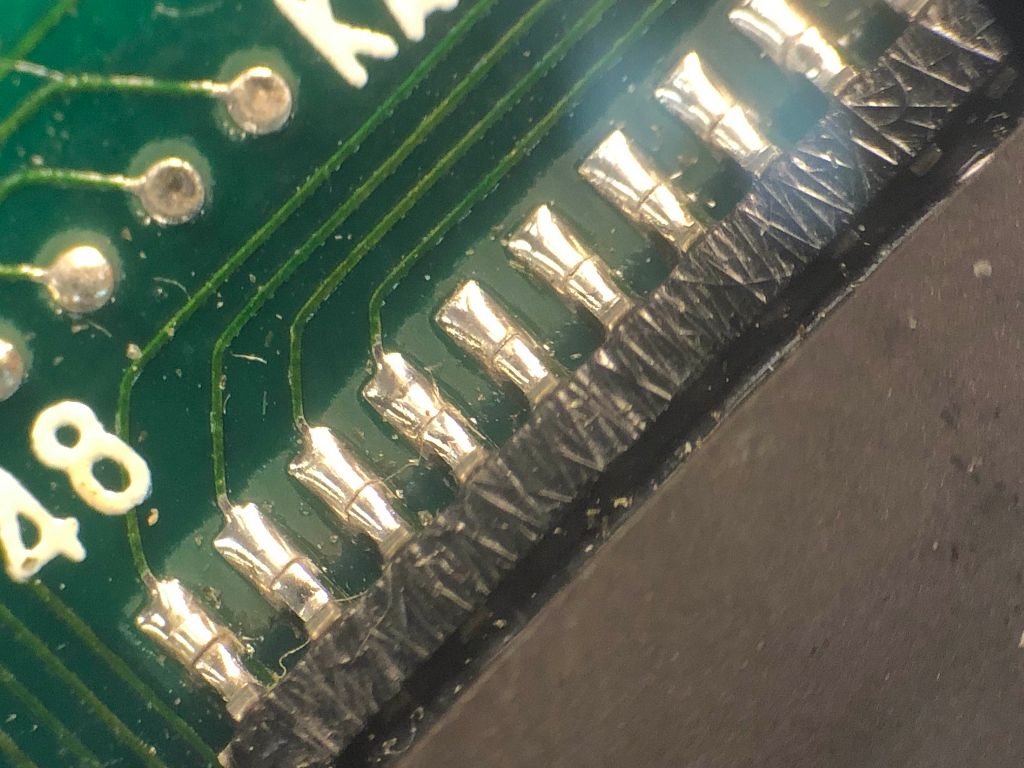

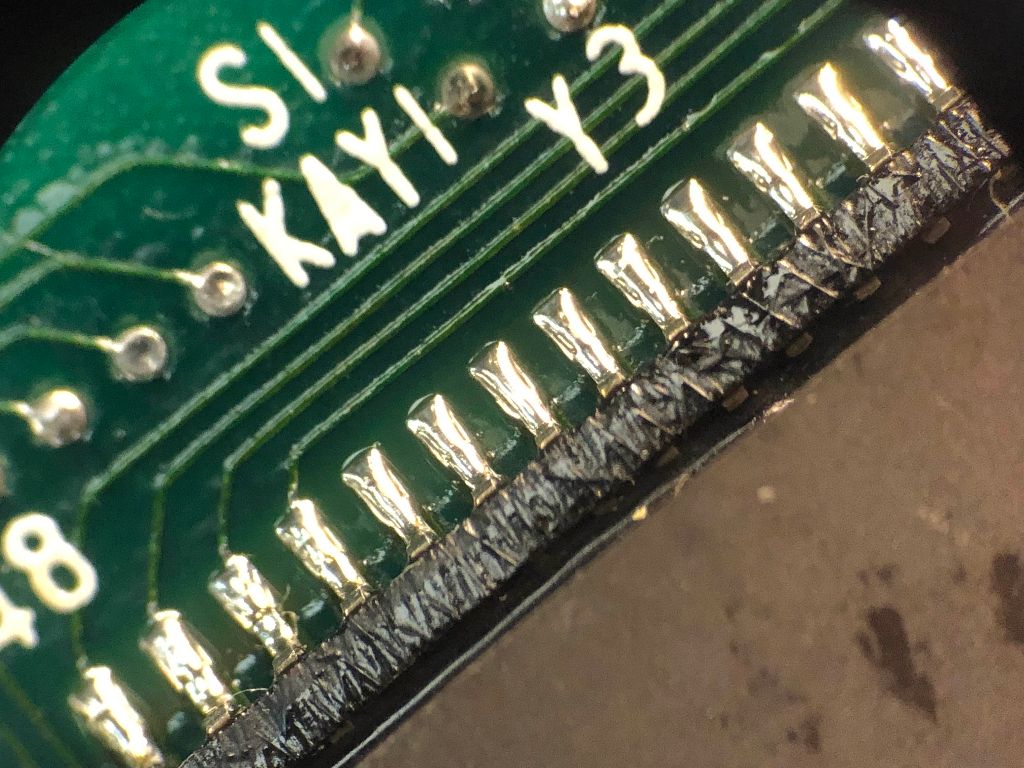

Component side. It uses common WDC chip

View attachment 1287864

The controller is connected to motherboard with an IDC cable, 34 pin as I counted. I believe it carries partially decoded ISA power.

I have mapped 26 pin floppy connector (next to power supply). In 3P it is directly routed to external DB25 floppy connector using flex cable, basically 1-1 pin mapping. In base gridcase 3 I believe it is directly connected to internal floppy and routed to external floppy too. PDF attached.

I have also attached STL file for 3d printing enclosure to hold together MFM controller + DREM + external floppy connector. (hdd plate no fdd v10.zip). I tried to sandwich it all together with bare gotek board but there is not enough vertical space ;(

Also, HDD image with DREM config (gridcase3p.zip)

And low lever format (llf13.zip) I used to format DREM.

The MFM controller is unique to GRiD. Maybe if you map the connector you could connect some ISA device, there but if it is already partially decoded you may be out of luck. but maybe if it is just IO/data + power and some other ISA signals maybe you can solder someting like XT IDE board there with compact flash?

Also, random JVC drives will probably not work, I think you need specifically JD-S3812M0R0, it has special protective plastic underneath to insulate from controller PCB and possibly other stuff for GRiD.

I think your best course of action is to burn 4 128KB EPROMs or 27C010 equivalent flash chips with GRiD DOS 3.3 and anything you want permanently available and add a GOTEK in place of FDD. unless you find broken gridcase and salvage the hdd controller.

Also, how is your plasma? I have two 3Ps and both have effed up displays with missing lines and some weird pattern spreading on screen when scrolling and so on ;(