Today was a holiday in RI, so I had some more time to work on the PDP-9.

I ran MAINDEC-9A D3BB-PB TC02 Basic Exerciser test #11, TC02 Instruction Test to see if the issues we had with the Status Register A write/read pattern test were fixed by swapping the S202 flipchips that make up the register. It behaved better because the first bit that was tested was the ENI (Enable Interrupt) and we had swapped the S202 for that bit. Now Function Register bit #3 was failing. Since we are only using TU55 #0 at this point I swapped the S202 that held the ENI bit for the S202 that held two of the tape drive bits. Now whole register passed the diags. We need to investigate this further. I don't like the idea that certain flipchips will only work in certain slots in the TC02. It is possible that I improved the electrical connection between the flipchips and the backplane by moving them, or the circuits for the tape drive unit number are less loaded than the circuits for the Function Register and Enable Interrupt and two of the S202 flipchips have weak transistors.

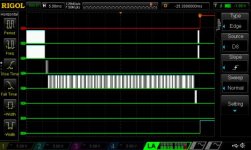

After the register tests, the diag starts testing the basic functions of the TC02. It tests skip instructions, interrupts, status conditions, error conditions, and then moves the tape and tests databreak. It failed at this point where it was looking for a second databreak to happen and it didn't. The MR (Mark Track Read) error light was on, so that might have stopped the tape motion and the second databreak. If there really was a Mark Track error it could be caused by tape head skew because we replaced the TU55 tape head, problems with the tape that I formatted on my PDP-8/e, or more problems in the TC02 controller. I will format another DECtape in PDP-9 format on my PDP-8/e, and we can also try a PDP-10 tape we have that was formatted on a KL10 to eliminate the tape format problem. We can borrow a different TU55 from the PDP-8/I to eliminate the tape head skew problem, and we will continue digging into the TC02 controller to see if something else is broken.

We are making progress, and eventually we will get it working. Then we can try a modified version of DumpRest to write an ADSS image to a DECtape and see if the PDP-9 will boot and run an OS.