week3

Member

Board version: 320132

Question:

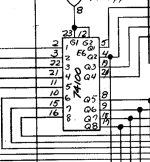

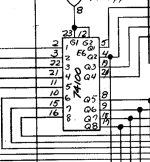

On E6 are 23 and 12 supposed to be shorted together? And if so are they shorted with a trace or a jumper or on the IC?

This feels like a silly question but my board is generating a bad vertical sync signal and I've traced it back to E6.23, E6.12 not being shorted together. I don't see the trace that connects them on the board but maybe its below the IC. Either way before I start shorting things together that I feel should already be connected I wanted to come to yall for a sanity check.

Background (A long winded unnecessary online cooking recipe esq story. You can ignore this and still be able to answer the question):

Bought this pet awhile ago at an estate sale non functioning. Got inside it and found out rats had been living in the board along with a bunch of bugs. Spent a ton of time trying to clean the board as esd safe as I could but eventually lost motivation and went onto other projects. Started working on it again recently. New to working on PETs and old computers in general but I've been having fun.

Issue: When it powers on the CRT shows a solid horizontal line.

Power rails - Fine

8MHz clock - Fine

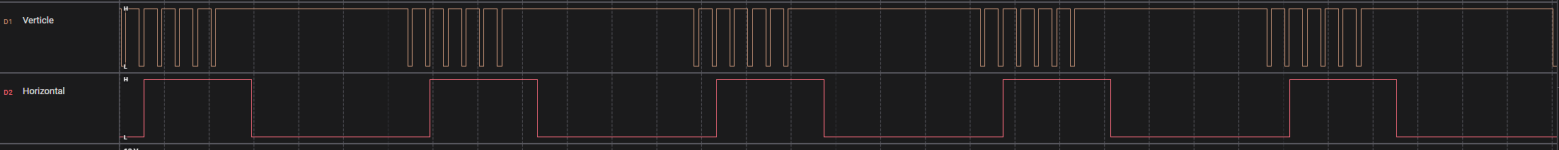

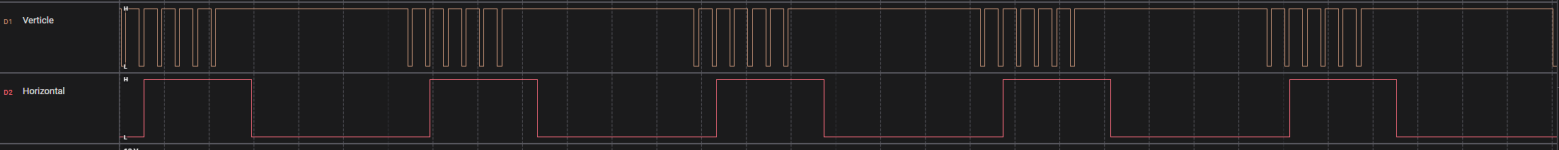

Vertical Drive Output on the PCB - Wayyyyy faster then 60Hz see "Video Signal.png"

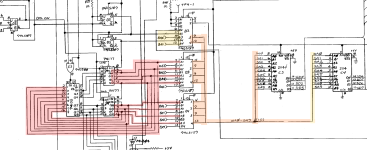

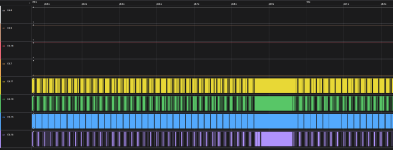

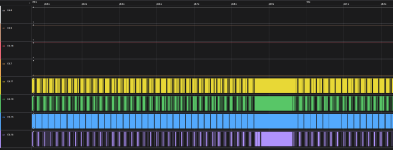

I then started going down the signal that generated the Vertical Drive output with a logic analyzer on each IC. Since its a repetitive signal I just watched the inputs/outputs and compared them to their logic tables to see if they were "good".

I can post scope captures if wanted but I determined that these signals were "Good"

D8 - 11,12,13

B6 - As a whole

C7 - 1,3,2,4,12

C9 - 1,2,3,9,8,11

^Well idk how much attention I paid to 2/3

C6 - 11,12,13

^Pin 13 Seemed to be on all the time so I started exploring down that route. Throwing Pin 13 high all the time on the falstad simulator generates the same vertical sync issue that I am experiencing.

Then I got to D8 which comparing to the falstad simulation felt like it had really wrong inputs

Tackling them one at a time I started exploring up E8. Pins 1,2,5 and 4 were high all the time. All its inputs.

So then I looked at the E6 latch that feeds it and saw that the latch that feeds it. The second latch on the IC. Isn't latching. I don't know why E6.7 is showing low when it was high in the feed to E8. Im guessing I hooked one of them up wrong for the capture will scope again when I get home.

Which then I looked at the latching signals for E6 and forgive me I forgot to get the scope capture. Will get another one tonight when I can work on it again. But Pin 23 (G1) had a signal going to it and pin 12 (G2) didn't. This makes sense because the second latch the IC isn't latching. Then when I check continuity between the two they are not shorted together. Which is weird because they show shorted together on the schematic but I can't see the trace connecting them when I visually inspect the board. I was wondering if jumpering them is fine or if I'm missing something?

Question:

On E6 are 23 and 12 supposed to be shorted together? And if so are they shorted with a trace or a jumper or on the IC?

This feels like a silly question but my board is generating a bad vertical sync signal and I've traced it back to E6.23, E6.12 not being shorted together. I don't see the trace that connects them on the board but maybe its below the IC. Either way before I start shorting things together that I feel should already be connected I wanted to come to yall for a sanity check.

Background (A long winded unnecessary online cooking recipe esq story. You can ignore this and still be able to answer the question):

Bought this pet awhile ago at an estate sale non functioning. Got inside it and found out rats had been living in the board along with a bunch of bugs. Spent a ton of time trying to clean the board as esd safe as I could but eventually lost motivation and went onto other projects. Started working on it again recently. New to working on PETs and old computers in general but I've been having fun.

Issue: When it powers on the CRT shows a solid horizontal line.

Power rails - Fine

8MHz clock - Fine

Vertical Drive Output on the PCB - Wayyyyy faster then 60Hz see "Video Signal.png"

I then started going down the signal that generated the Vertical Drive output with a logic analyzer on each IC. Since its a repetitive signal I just watched the inputs/outputs and compared them to their logic tables to see if they were "good".

I can post scope captures if wanted but I determined that these signals were "Good"

D8 - 11,12,13

B6 - As a whole

C7 - 1,3,2,4,12

C9 - 1,2,3,9,8,11

^Well idk how much attention I paid to 2/3

C6 - 11,12,13

^Pin 13 Seemed to be on all the time so I started exploring down that route. Throwing Pin 13 high all the time on the falstad simulator generates the same vertical sync issue that I am experiencing.

Then I got to D8 which comparing to the falstad simulation felt like it had really wrong inputs

Tackling them one at a time I started exploring up E8. Pins 1,2,5 and 4 were high all the time. All its inputs.

So then I looked at the E6 latch that feeds it and saw that the latch that feeds it. The second latch on the IC. Isn't latching. I don't know why E6.7 is showing low when it was high in the feed to E8. Im guessing I hooked one of them up wrong for the capture will scope again when I get home.

Which then I looked at the latching signals for E6 and forgive me I forgot to get the scope capture. Will get another one tonight when I can work on it again. But Pin 23 (G1) had a signal going to it and pin 12 (G2) didn't. This makes sense because the second latch the IC isn't latching. Then when I check continuity between the two they are not shorted together. Which is weird because they show shorted together on the schematic but I can't see the trace connecting them when I visually inspect the board. I was wondering if jumpering them is fine or if I'm missing something?