dabone

Veteran Member

I just bought a 4016 9" with a 320350 motherboard, and I'm having a time getting anything out of it.

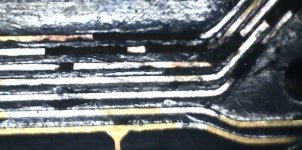

Occasionally it would run PETTESTERV4, but not anything else, and sometimes it would take leaving it on for 30 mins or so before anything runs.

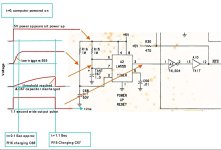

I washed the board yesterday, and tonight I got out the probe, and pin 3 of the 555 @ a3 (the reset circuit) never goes low, but always stays high.

I didn't leave it running for a long time to see if it ever comes out of reset today.

I don't have any 555's in stock, so recommendations before I order more parts?

Thanks.

Occasionally it would run PETTESTERV4, but not anything else, and sometimes it would take leaving it on for 30 mins or so before anything runs.

I washed the board yesterday, and tonight I got out the probe, and pin 3 of the 555 @ a3 (the reset circuit) never goes low, but always stays high.

I didn't leave it running for a long time to see if it ever comes out of reset today.

I don't have any 555's in stock, so recommendations before I order more parts?

Thanks.