derelictronics

Experienced Member

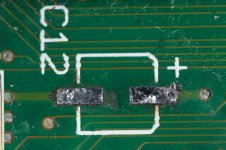

I have an SE/30 collecting dust that needs recapped. I'm contemplating doing it myself (have the solder tools available at the local hackerspace). But, if there are people offering recap services for cheap enough, I'd be tempted to pay somebody to do it for me.

Can any of you recommend a somebody? If not, I need to find the specific capacitors needed. The values are listed at the site below. Maybe somebody sells a pre-packaged capacitor kit already?

http://www.maccaps.com/MacCaps/Capacitor_Reference/Entries/1989/1/19_Macintosh_SE_30.html

Can any of you recommend a somebody? If not, I need to find the specific capacitors needed. The values are listed at the site below. Maybe somebody sells a pre-packaged capacitor kit already?

http://www.maccaps.com/MacCaps/Capacitor_Reference/Entries/1989/1/19_Macintosh_SE_30.html