Hello kind gentlemen!

OH NO DavidL, please don’t give up on me!

I do still <3 love <3 all of you and I greatly appreciate the hard work in testing my pads by all of you and I appreciate the in-depth feedback, greatly. I just saw the posts yesterday, I have been super busy the last few days so I was a bit slow on checking back. I just saw the subscribe to thread option too.

When I did see the posts I also got a little obsessed because the forum was not loading correctly across 4 different browsers. The stylesheet is not loading so reading through the forum in straight HTML without the stylesheet is a little cumbersome. It’s loading in Edge now, so here I am. Anyone having this issue in Firefox? I can’t seem to fix it, cleared cache and cookies and my browser is up to date. Sorry got off topic there.

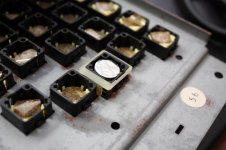

Anyway, all that said I am reading through and am now on the hunt for new foam. I saw billdeg was using Track-bed about a week or so ago on his website so I was already considering this. I have been digging over here.

Now I am contemplating height and hoping to find out exactly what that foam is made of as I would like to buy it in larger sizes, preferably by the roll and not a 1 ¾” wide roll. I know it’s open-cell and according to the Track-bed site it will not quickly deteriorate, however that promotional video appears to be relatively dated. At least that means it shouldn’t be going away anytime soon, right? I’m not ruling it out as I can at least buy it by the sheet.

I will need testers guys, so please don’t give up on me guys! :hugs:

OK, checking my private messages now.