Eudimorphodon

Veteran Member

MCM6574P keyboard chips

Isn't that a character generator?

Anyway, I guess the point I was making is, well, if you have a "Subsystem B" you pretty much already have a SOL-20; the ROM on the GPM board *is* the "Personality Module", and it seems in principle you could change it out for whatever you want. So for your own needs it'd seem like you'd be covered without building anything?

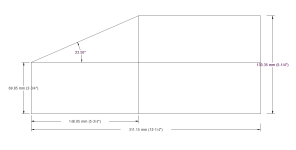

Maybe this is an ignorant way of looking at it, but isn't most of the "secret sauce" that distinguishes a SOL-20 from a vanilla 8080-powered S-100 machine the unique aspects of the VDM-1 video board? I guess I'm wondering if the definition of "reproduction" were expanded to include hardware that used more modern components for availability/chip count reasons what would be the exact level of fidelity necessary to run, say, the majority of the non-CP/M software on Sol-20.org's archive. Or is this all about just churning out a copy of the original PCB board specifically?

I guess maybe it's an interesting thought exercise to ponder how one could make a simplified Sol-20 compatible with "more modern" parts but stopping short of just cramming it all in an FPGA or CPLDs. Looking through the schematic parts of it are *very* obsolete, like the TMS6011 UARTs that are used for both the serial port and cassette interface. (I mean, I guess it looks like maybe the TR1602 might be close to a direct replacement, but that's still long gone...)

Last edited: