Ansgar Kueckes

Member

- Joined

- Feb 11, 2024

- Messages

- 41

Thanks for volunteering, whatever you find, it will be invaluable. I have also updated your silkscreen findings with the Rev D version.Got my last part! put it all together, fired it up and ran GDEMO.COM and .... nothing!.. tried KSCOPE.COM and .... nothing again. darn.. black screen.

Sanity check: this is meant to plug into a standard composite video monitor right? So an AppleColor Composite or Commodore 1702 should work?

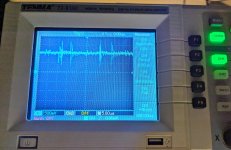

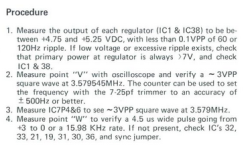

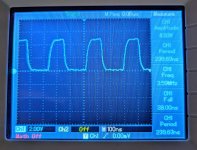

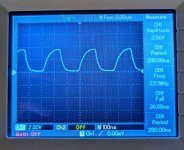

Guess it's time to go back through everything with a fine-tooth comb. The manual gives a test/tuning routine which relies on a front panel which I don't have. Was there any other diagnostics software?

My problem with the KiCAD files is that it is difficult to check them against the schematics. Most routes consist of multiple segments, which are not easy to check against the schematics when you can't highlight the complete interconnect between pads. Which however normally is the first step, so that you can have your focus on the components rather than on the PCB. But you can of course check the routes relatively easy on the PCB once it has been produced. I guess it is important to make sure all connections are *really* consistant with the schematics before starting to trace the gates.

The components (at least the ICs) in general are old enough that with a certain amount of ICs, always some of them are not fully working. It was interesting that Hugo's board worked from the start. Mostly replicas built with vintage components require some care before they work as expected. This is at least my experience.

I don't know of any diagnostics other than those in the original manual. It is a really great feature to be able to step through the code with a front panel