View attachment 1267417

The government site for my areas says:

"Australian standards require electricity to be supplied at 230 V

(+10% to -6%), therefore providing an allowable voltage supply

range between 253 V to 216 V. Voltage is generally supplied to NSW

users between 250 V and 240 V"

I live in QLD.

The line voltage here can get very high.

One of the reasons is our grid was designed to deliver energy, with a voltage drop along the line. But now energy is injected into it by solar installations. Their inverters are designed to cut off at 255V, but some people figure out how to reprogram that higher, so they can keep connected. In any case the regulation is degraded in that the voltage swings on the power grid have increased as well as many homes receiving around 250 at times when it is supposed to be 230v

This causes a lot of trouble, especially with American line transformers running via step-down transformers, because they were designed for 60Hz use and the peak core flux increases by a factor of 60/50 and if you run them from 120V , 60 HZ, in terms of peak core flux, this is as though you were running them from 120/110 x 60/50 x 110 = 144 volts in the USA, the cores saturate, they overheat and radiate large magnetic fields due to the high primary magnetization current. In many cases the primary should be run at around 95 to 100v on 50 Hz, if the secondary voltage remains high enough to get away with that.

Luckily though your PET transformer is designed for 50 and 60Hz operation, but the primary voltage, to help run the regulators cooler is probably better around 220 to 230V

The problem for my workshop at my home got so bad that I had installed a 15kW rated autotransformer, made by a Sydney company, to knock the entire house voltage down to 230V. This has multiple benefits for appliances, but certainly workshop gear and items with analog regulators in them. (I call it my Solar Defense transformer)

For my American vintage computers I run them via a variac too that generally feeds them with 95 to 100V. In one case I built an auto-regulating variac which cures the line voltage fluctuations, so I can set the running voltage just above where ripple breaks through to the output of the analog regulators. This means the computer (in this case a SOL-20) analog regulator's run as cool as possible.

Silicon Chip magazine did an article on it and they can supply the pcb:

here was my original article:

www.worldphaco.com/uploads/THE_CONSTANT_VOLTAGE_MACHINE.pdf

The best thing for you though, if you don't have one, is to feed your PET via a Variac to knock back the line voltage (some people put a bucking transformer in, I'm not fond of that).

Jaycar sell a well priced variac:

The variable autotransformer (Variac is the trade name of a popular brand) is one of the most useful and efficient devices ever invented for the contr...

www.jaycar.com.au

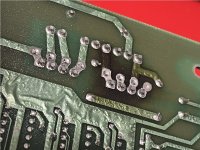

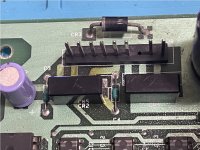

The procedure is you start with the variac around 1:1 wind it back until you see disturbances in the video (corresponding to ripple in the %v supply) then increase it by about 5 to 10V to allow for line fluctuations. With the 9" PET VDU, as soon as any ripple appears in the video, the raster scan bounces up and down because of the positive feedback around it. This can also be a symptom, even with normal line voltage, of the main capacitor losing capacitance.