Hugo Holden

Veteran Member

It makes sense too, because the original MOS 2114's are generally defective now, but those NEC ones are usually ok !

| VCF West | Aug 01 - 02 2025, | CHM, Mountain View, CA |

| VCF Midwest | Sep 13 - 14 2025, | Schaumburg, IL |

| VCF Montreal | Jan 24 - 25, 2026, | RMC Saint Jean, Montreal, Canada |

| VCF SoCal | Feb 14 - 15, 2026, | Hotel Fera, Orange CA |

| VCF Southwest | June, 2025 | University of Texas at Dallas |

| VCF Southeast | June, 2025 | Atlanta, GA |

I'll check the sync pin with the PETTEST installed tomorrow... ...er... later-If the CPU pin 7 (SYNC) is still pulsing, the PETTESTER ROM and socket is fine.

If you have swapped the DRAMs around (and you are swapping the DRAMs on the correct 16K bank of memory) the problem must be related to either the data bus buffers or the address multiplexing.

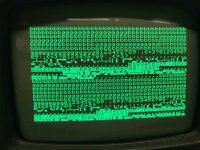

It looks like address $00FF is OK, so (if it is a data bus buffer) we have some bits stuck high.

Remind me, which PET are we repairing? I have so many on the go at the moment...

Just going out for a walk...

Dave

Ah, the curse of having hobbies. Best wishes with... surviving, on my behalf!Ah, I was about to post some of my findings and save you some wasted time. The wife has been out this morning so I thought I would take the opportunity to tidy up my work room. This involved filling other parts of the house with stuff that would have incurred wrath and indignation had she been aware of it! Anyhow, what the eye doesn't see...

The errors indicate that buffered data bits D5 and D6 are stuck high - thus pointing the finger at I11 or E10.

However, the address bus multiplexers could also cause similar problems (E3 to E6).

Always read the data sheets and seek advice before replacing a part with something else other than the original.

Dave

Yes indeed I do. I have a scope, meter and basic soldering / desoldering equipment, and a load of second hand assorted components like DIP sockets etc.Before you start replacing parts, remind me - do you have an oscilloscope or not?

Dave

Ultimately I acknowledge that I am but a hobbyist and my knowledge is limited to what I've figured out on my own and what I've learned from folks like yourselves. If I had a graph indicating an expected waveform and a reference to roughly where on the schematics it is, I could probably check it.So, using your scope to take measurements is a much better solution than randomly replacing parts.

How much knowledge do you have of electronic schematics and the use of the oscilloscope?

I have a meeting now...

Dave

I recorded most of the signals that control the 4116 DRAM in the dynamic PET, might help you as a reference, they are in this article about finding defective DRAM;Ultimately I acknowledge that I am but a hobbyist and my knowledge is limited to what I've figured out on my own and what I've learned from folks like yourselves. If I had a graph indicating an expected waveform and a reference to roughly where on the schematics it is, I could probably check it.

Ah I see, that makes sense. Thank you for explaining! I presume then that a low signal on those pins would indicate a solid 0V connection (not something I've had to measure before)?If you look at the schematic for E3 to E6 you should see that some pins (other than the power 0V pin) is/are connected to 0V.

What we are doing with this test is to make sure that the PCB tracking is OK and that the pin(s) really are connected to 0V when they should be! If not, the IC will malfunction in operation.

It is a quick check, so worth doing - even if a fault like this is statistically small. It has been known...

Dave

That's really helpful too, might need it for diagnostics as I go about testing, so that I have something to compare to. I'll check it out...I recorded most of the signals that control the 4116 DRAM in the dynamic PET, might help you as a reference, they are in this article about finding defective DRAM;

www.worldphaco.com/uploads/DRAM%20MEMORY%20TEST%20SYSTEM%20FOR%20THE%20DYNAMIC%20PET%20COMPUTER.pdf

Commodore did not use any pullup resistors on the outputs of the DRAM IC's. Have a look at pdf pages 11 and 12 of the article I posted. It pays to know about this when interpreting defective bytes returned from the malfunctioning memory IC array, when trying to figure out which chip/chips are faulty. The idea of the article was to figure out which ones, to avoid unsoldering perfectly good ones.

I have a policy about removing vintage DIL chips from boards:

1) the most important part to preserve is the pcb.

2) only remove chips that appear to be highly likely defective on in circuit testing & analysis.

3) Unless it is a super rare unobtainium chip, destroy the chip by cutting off its legs close to its body with fine needle nosed cutters, then remove the pins one by one and add fresh solder and clear the holes with the sucker. Using a temp controlled soldering iron.

4) don't remove whole IC's for the purpose of testing, or any plan that they might be put back in the computer.

It is all about having less thermal and physical stress applied to the pcb, not saving the chips as a priority, unless they are very rare parts, then save them. The chips get saved by the process of testing and analysis in circuit, so that it becomes unlikely that good ones are removed by accident. It helps greatly if sockets are already fitted.

When chips are removed to save them, sometimes small areas of the pin surface is still stuck to the inside of the plated through hole and can pull pieces out or lift pads, unless the pins are completely free, which can sometimes be difficult, even with a good sucker. Though, when the pins are removed one by one, it is effortless to clear the hole with one attempt with the sucker, in most cases unless there is significant thermal relief around the hole.

Some years ago I used a de-soldering tool for 14 & 16 pin DIL IC's that heated all the pins simultaneously to extract chips intact. Overall though, it was more stressful for the pcb and occasionally caused some damage. I have similar tools too, but now I reserve these for surface mount IC's, where it is the safest way to remove them.

The reason I'm mentioning these things, is that if chip un-soldering for "testing or replacement" is used as a random repair methodology it can result in a total disaster. There can be introduced faults from pcb damage, unsuitable replacement parts etc. Then the faults on the board start to multiply. Once I helped fix a Pong pcb that had about 65 TTL IC's. The technician had replaced probably 40 of them on hunches. Still, the board remained faulty. After all of the damaged from this was rectified (which was a very large job and the pcb would never be the same), the original faulty chip was found (with the scope) as being one of the remaining original ones, but even if that had got replaced more than a few of the other IC changes into the process, the board still would not have worked due to introduced faults.

It is somewhat unfortunate that the presence of cheap logic IC testers have appeared, because it has encouraged some people to use these as a "repair tool" removing, testing, and re-fitting chips on vintage computer boards, which is non ideal from the perspective of pcb preservation. The testers are really better deployed testing old stock IC's prior to use, to screen out duds, rather than as a repair tool. There is also no guarantee that if a tester reports a particular chip as ok, that it will definitely work in the particular circuit location. Some testers also report chips as duds, when they are not too. I think it still remains true that to test an IC on a vintage computer board, the better place to test it is right there, in the circuit it is in, on the pcb, before concluding it is defective and removing it. For most of the common TTL logic IC's, it is a matter of seeing if they are obeying their truth table with the scope or logic analyzer.