SomeGuy

Veteran Member

When trying to reconstruct damaged data without the original media, having more revolutions usually increases the chance of being able to piece bits back together.(OP) Two further points for discussion.

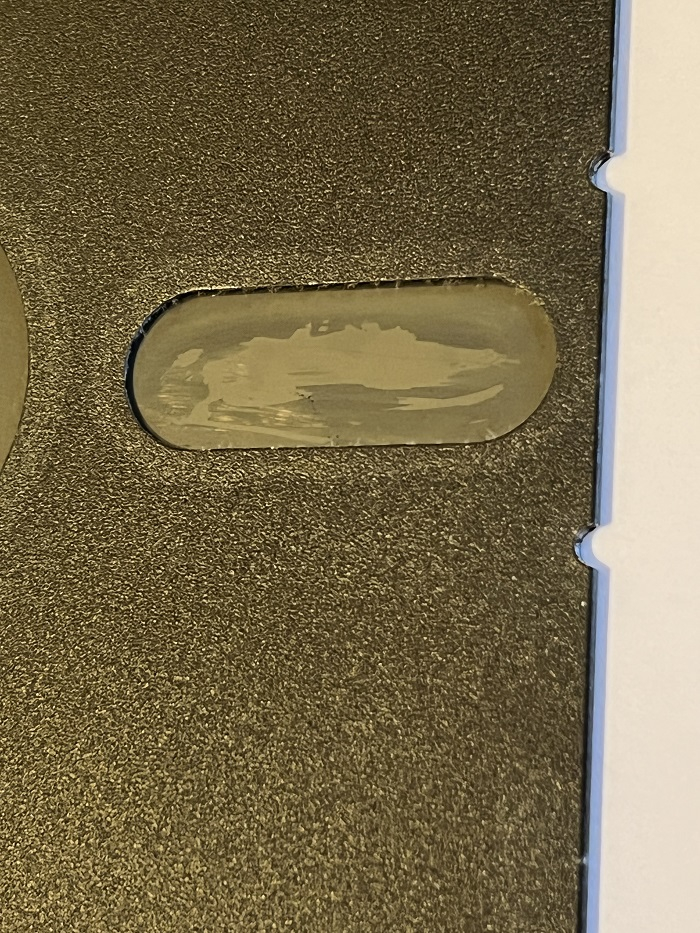

2. Flux reading devices (GW, KF, CW, etc.) may default to reading each track multiple times, with the opportunity to specify the number of reads in the command line. Since loss of oxide may be proportional to the number of reads, reducing the number to 1 or 2 might be better than 3, 4 or 5.

Any comments/discussion on these points would be welcome.

When a disk ISN'T shedding, a "bad" area may actually start reading OK after a number of revolutions as the heads scrape away dust and gunk.

In practice, I have found 5 revolutions, as the kryoflux defaults, to be a good midground between too many and too few.