Upcoming Events:

- VCF South West - June 14 - 16, Davidson-Gundy Alumni Center at University of Texas at Dallas

- VCF West - Aug 2 - 3, Computer History Museum, Mountain View, CA

- VCF Midwest - Sept 7 - 8 2024, Schaumburg, IL

- VCF SoCal - Mid February 2025, Location TBD, Southern CA

- VCF East - April 2025, Infoage Museum, Wall NJ

-

Please review our updated Terms and Rules here

- Forums

- Companies

- IBM Computers, PCs, Clones and Descendants

- PCs and Clones (XT and early AT class machines)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Faulty 5150 Motherboard

- Thread starter VeryVon

- Start date

maxtherabbit

Veteran Member

Congrats on getting it booting. I'd suggest running a more thorough memory test now, like in checkit.

fdiskitup

Experienced Member

A fine breeding pair, be careful you don't end up with an IBM Jr...

Cyberstein

Experienced Member

- Joined

- Dec 26, 2021

- Messages

- 64

I just purchased an IBM 5150 which has this Lung Hwa 623MF Multifunction card mention above. It appears to be 100% functional, at least in terms of RAM, serial port and parallel port. It passed all tests in Check-It. The RTC battery was dead though and I replaced it. But I have been unable to find any documentation or software in regards to setting the clock. I tried my AST software with it and also the PII-125 from "minuszerodegrees.com". Neither work. Does anybody have any documentation or software for this card? I'd appreciate any info or help anyone can provide. Thanks!

modem7

10k Member

So, from post #32, you noted that the 623MF multi-function card contains an Oki M5832 RTC chip (or maybe sometimes, an equivalent was fitted).I just purchased an IBM 5150 which has this Lung Hwa 623MF Multifunction card mention above. It appears to be 100% functional, at least in terms of RAM, serial port and parallel port. It passed all tests in Check-It. The RTC battery was dead though and I replaced it. But I have been unable to find any documentation or software in regards to setting the clock. I tried my AST software with it and also the PII-125 from "minuszerodegrees.com". Neither work. Does anybody have any documentation or software for this card? I'd appreciate any info or help anyone can provide. Thanks!

You unsuccessfully tried the RTC software for DTK's PII-125 card, from [here], because that card also uses an Oki M5832 chip.

That failure may be due to:

- The RTC related circuitry is faulty on your card.

- On your 623MF card, switches/jumpers are presently set to disable the RTC functionality.

- Although DTK's PII-125 card also contains an Oki M5832 chip, it could be the that the M5832 on the 623MF card starts at a different base I/O port (therefore possibly requiring different RTC software).

On the 623MF card, maybe switches/jumpers alter the base I/O port of the RTC, possibly allowing a base I/O port that works with the RTC software for DTK's PII-125 card.

At [here], related information is in the thread pointed in the entry for the Premier Technologies Z148X.

@Cyberstein / @modem7 if there's any tests you'd like me to perform to verify what you're seeing let me know. I haven't replaced the battery on my card, but I have one I can put on there if needed.

modem7

10k Member

Must be. 'Thompson, Harriman and Edwards' is on the floppy label, and on the card's FCC sticker.I'm also attaching files & disk image (both same files) from the floppy that came with my 5150, I believe it's the original software for the multi-function card.

Probable use:

- Per [here], SETCLOCK.EXE is used once to set the date/time into the RTC.

- DATETIME.COM put into AUTOEXEC.BAT

modem7

10k Member

Once SETCLOCK.EXE and DATETIME.COM have been confirmed as suitable for the 623MF, I will add the software to [here].Must be. 'Thompson, Harriman and Edwards' is on the floppy label, and on the card's FCC sticker.

Probable use:

- Per [here], SETCLOCK.EXE is used once to set the date/time into the RTC.

- DATETIME.COM put into AUTOEXEC.BAT

Cyberstein

Experienced Member

- Joined

- Dec 26, 2021

- Messages

- 64

Outstanding guys! Let me give this a try, I just got some time to get back to it. I'll let you know, thanks again!

Cyberstein

Experienced Member

- Joined

- Dec 26, 2021

- Messages

- 64

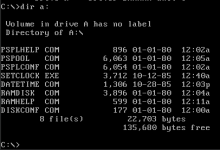

Okay gentlemen, that did the trick, my 5150 is now 100% fully restored! I have posted some pictures to show the results. You can see I removed the original hard leaded battery and replaced with a soft leaded 2032 battery holder. I used to RTV to provide strain relief on the solder joints and Velcro to mount it to the back of the card. The software you provided is straight forward and runs as we suspected. You simply run the "SETCLOCK.EXE" and it gives the menu shown in the pictures. You press 'D' to set the date and 'T' to set the time. Once this is done, you run the "DATETIME.COM" in your "AUTOEXEC.BAT" where it set's/displays the date/time on boot. Easy money! It's not Y2K compliant though, threw error when I tried inputting >1999. No big deal though. Thanks again VeryVon and Modem7!!!!

Attachments

Cyberstein

Experienced Member

- Joined

- Dec 26, 2021

- Messages

- 64

Just to share, I also had to repair both Tandon drives on this unit. They had the usual shorted tantalums and what not, which I recapped. And while I was doing this I of course, I oiled/cleaned them. Which is where I noticed the pulley on drive B was severely deformed and cracked. Bad enough where it could not freely spin, prohibiting the drive from functioning. This is the first time I have seen a part any computer do this, especially an IBM. It's almost as if the part is a knockoff made out of clay. I am almost 100% sure this is the original drive that came with the PC, it even has the original box with matching serial numbers. Luckily I have a spare scrap Tandon for parts that I could get a replacement pulley from. I just wanted to share because I own quite a few IBM's with Tandon's and have never seen this before. Have you?

Attachments

maxtherabbit

Veteran Member

Why? Seems like a step backwards to be honest.Okay gentlemen, that did the trick, my 5150 is now 100% fully restored! I have posted some pictures to show the results. You can see I removed the original hard leaded battery and replaced with a soft leaded 2032 battery holder.

Cyberstein

Experienced Member

- Joined

- Dec 26, 2021

- Messages

- 64

Not sure what you mean there, could you clarify please? Do you mean the battery holder position? The holder is low profile and will not interfere with adjacent boards, non-conductive as well. Allows easy replacement of the battery in the future. Mounting in original location on top didn't quite fit and required mounting it on top of the wire solder joints. I also thought about hard leading another one in there to keep it original. But this would degrade the board in the future when one has to de-solder/solder to replace it again. I am sure there are 101 better ways, but I already had this part and it works good for me.Why? Seems like a step backwards to be honest.

modem7

10k Member

Not me.Which is where I noticed the pulley on drive B was severely deformed and cracked ... and have never seen this before. Have you?

Cyberstein

Experienced Member

- Joined

- Dec 26, 2021

- Messages

- 64

Or perhaps you mean the Y2K compliance? Functionality is what matters to me, not capability. I just want it to be 100% functional and restored to its original glory. This is actually my 3rd IBM 5150 and I do have other RTC/RAM cards I could install that are Y2K compliant. But this is the one that came with this machine originally, so I'd like to keep it that way as long as possible. Call me crazy, I don't care. If I wanted capability, I wouldn't be using/collecting 1980's computers LOL.Why? Seems like a step backwards to be honest.

maxtherabbit

Veteran Member

I mean why didnt you just put a new battery in the original battery holder?Not sure what you mean there, could you clarify please? Do you mean the battery holder position? The holder is low profile and will not interfere with adjacent boards, non-conductive as well. Allows easy replacement of the battery in the future. Mounting in original location on top didn't quite fit and required mounting it on top of the wire solder joints. I also thought about hard leading another one in there to keep it original. But this would degrade the board in the future when one has to de-solder/solder to replace it again. I am sure there are 101 better ways, but I already had this part and it works good for me.