First check: during boot sequence, just before the login prompt, the printer should be turned on by the main unit (you should hear the click of the relè, then the fan, then the motor should be spinning for approximately one second). If there’s some paper sheet half the way in, the printer should eject it.

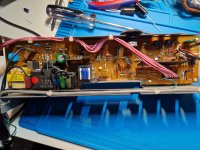

In my case, before recapping nothing was moving, just the fan. After recapping, the motor came back to life. The fan is dynamically driven, so upon printing it spins faster, you can clearly hear a higher pitch.

No need to have the lower case installed, I actually operated the machine without the top cover, too (you need to cheat by keeping the cover sensor triggered with some tape, though…).

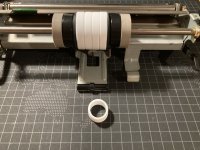

Effective pick up rollers are key, though. For the initial feeding step, the roller will just make one turn or so. If the paper reaches the registration rollers, then the feeder will keep on turning, else it will stop and the machine will throw the paper jam error. I would definitely try to force some more grip into the roller (e.g. with rubber bands) for making sure the issue is not there.

Over the week end I plan to wrap up the whole thing, I will try to make and share some movies for reference.