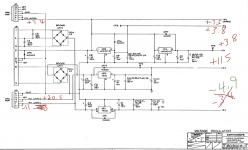

Is it 2 volts per division?

yes, 2v/div.

measured at pin 6 of J12 which is marked in the schematic as +9 unregulated.

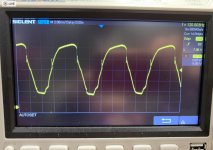

Is it 2 volts per division?

That is a lot of ripple. It is way too much. That is why I asked you to check it at the large capacitor. Use the negative post of the capacitor as your ground. There are two possibilities for that much ripple. One is the capacitor has dried out or that there is a heavy load of the power supply. Since you have a new capacitor coming in, it may solve the problem. If it is a load issue, it looks to be on the +5V outputs as you can see on the curve where the regulators kick in. I think it looks like the large capacitor as it drops way to fast below that.

Dwight

Thanks, Dwight, I was probably typing as you posted this. I truly want to understand how you read this so well from the scope. you were bang on!

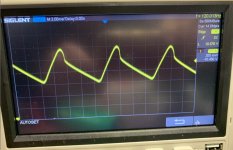

When you look at the second plot of the ripple, the first thing to notice is that the peak to peak is about 600 mv. Again, it is important to note the frequency. 60 Hz on a full wave rectification indicates an open diode.The next thing to notice is the tight shape of the wave. On the up swing, we are seeing the line following the input sine

wave. Just after the peak we see the shape break away form the sine path to a relatively constant slop until the sine wave peak catches up to it.

Now, looking at the first picture. Notice the shape is kind of following the sine wave but is clipping on something on the up sing. This is likely the regulators getting enough voltage to start conducting. Notice that the wave form goes almost all the way to zero. We are probably seeing the tiny effect of the 1 uF caps on the inputs to the regulators, keeping it from going all the way to zero. Even a shorted +5V would not track all the way down to zero as the regulators would stop conducting earlier. To be a load problem it would likely nee to be before the regulators, on the raw DC side. Since you were not complaining about a hot transformer, that leaves only a capacitive failure. As a dry capacitor would cause this wave form.

Dokken,

You did a good job on your computer.

I have a few questions. Was there no goo leaking out of the old capacitor? Or did capacitor dry out as Dwight mentioned? Is the replacement capacitor about the same size as the original? How did you attach it to the chassis?

OK, thanks to the forum team I learned something about power supplies from this problem. With no goo, I would have replaced the diode bridge and wasted time and effort with that first.