mechaniputer

Experienced Member

- Joined

- May 23, 2015

- Messages

- 59

I already removed the battery back on the day of the original posting. I'll try to clean up the corrosion with vinegar as suggested.

Yes, exactly right. This machine has particular nostalgic value and was the first computer I ever used. I'm now a computer science professor and would like to keep this exact machine going as long as I can. If the general concensus is that it's fine to wait until something blows and then probably be able to fix it, I'm willing to accept that. But also open to suggestions for more proactive routes.

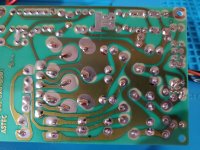

For those who decide, for whatever reason/s, to avail themselves of the service, some considerations:Find a recapping service and, if the price is right, have it done. There's very little risk in doing so.

We're not talking about custom ICs. We're not talking about FPGA chips. We're not talking about PGA chips. In fact we're not even talking about multi-pin through hole ICs. We're talking run of the mill, two leg, through hole capacitors. Unless there's some special circumstance these things a dirt easy to replace with minimal, dare I say almost no risk, to replacing them. Especially for someone who does it as a service.FWIW, I do maintenance on our vehicles and other equipment, as well as computer gear. But given the fragile nature of computer systems, I'd rather wait until a single component fails before picking up the soldering iron. Many custom ICs, for example, are unobtainium after a couple of decades; inadvertently damaging one can result in creating nothing more than e-waste when one previously had a functional computer.

After all, a 386 system isn't that old--and old systems are infinitely more repairable than modern ones with their tons of SMT and custom silicon--and lead-free solder.

I did not recap the motherboard. A recap of the motherboard was too high a liability for a board outside of the early 2000's capacitor issues and the board as-is was passing burn-in tests. Plus even with a recap there was nothing that said I would be back here having to recap again in 20 years, so why risk damage to the plated vias?

Just saying that the old boards can get touchy. If the service botches the job, will they make good with an exact replacement? If not, why take the risk? Or will they take the universal mulligan and say "damaged in shipping".We're not talking about custom ICs. We're not talking about FPGA chips. We're not talking about PGA chips. In fact we're not even talking about multi-pin through hole ICs. We're talking run of the mill, two leg, through hole capacitors. Unless there's some special circumstance these things a dirt easy to replace with minimal, dare I say almost no risk, to replacing them. Especially for someone who does it as a service.

That board was selected for the job. If it worked, then I recapped it as PM and now it wasn't working I just wasted a dozen or so capacitors and a bunch of my time, plus now I have to put the job on hold until another suitable board could be sourced.What made it too high of a liability? Maybe if you're talking about SMD caps (which aren't that difficult to replace either) but two leg, through hole?

A vehicle can kill you if an important part fails. That comparison is so off that it is just ridiculous and kind of shows a lack of real argumentation.Apparently several people here do not preventative maintenance / repairs on their vehicles and wait for something to fail before performing any work.

I've seen the work of many "recapping services". No risk? Most of them do a terrible job. And, of course, no one will ever give you any warranty for their work.Find a recapping service and, if the price is right, have it done. There's very little risk in doing so.

Just saying that the old boards can get touchy. If the service botches the job, will they make good with an exact replacement? If not, why take the risk? Or will they take the universal mulligan and say "damaged in shipping".

A vehicle can kill you if an important part fails. That comparison is so off that it is just ridiculous and kind of shows a lack of real argumentation.

Also, what's the deal anyway to always fight other people's opinions instead of just respecting them?

I've seen the work of many "recapping services". No risk? Most of them do a terrible job. And, of course, no one will ever give you any warranty for their work.

What some people don't seem to understand: BECAUSE the system is important to him, he should not mess around with it. If e.g. the mainboard takes damage, you can't just go buy a new identical one and replace it (and if you could, it would lose its uniqueness - no longer being the actual part from his past).

In the end, he can do whatever he wants. Still, my opinion is to use the system, have fun with it, and not take the soldering iron to fix what is not broken.

That board was selected for the job. If it worked, then I recapped it as PM and now it wasn't working I just wasted a dozen or so capacitors and a bunch of my time, plus now I have to put the job on hold until another suitable board could be sourced.

I know what I am doing*. That doesn't mean someone else is as good as I am, or that I compared to someone else with considerably more experience and more expensive tools is what you would call "professional".I'm having a difficult time understanding why it wouldn't work unless you don't know what you're doing.