Hi,

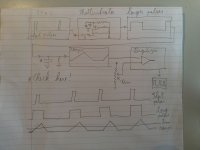

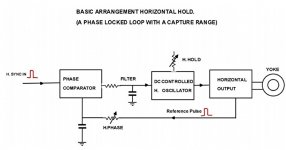

I am trying to fix my monitor. It seems like the horizontal sync is not OK. Things seem to be at the correct height.

The monitor is Olivetti CDU 1200 D12CS63, Toshiba , feb 1986 from Olivetti M24 computer. The video card is OK.

Here are some photos and a video: https://1drv.ms/u/s!AsoOXKPKfQ6FgsJarUMObkyYtrJMBw?e=9tczyo

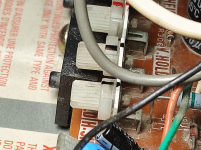

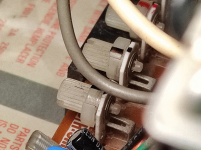

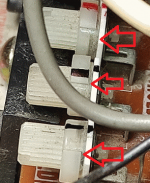

Can I do something without changing ICs? There are some white things at the back. Is there a way to adjust the horizontal sync with them?

I am trying to fix my monitor. It seems like the horizontal sync is not OK. Things seem to be at the correct height.

The monitor is Olivetti CDU 1200 D12CS63, Toshiba , feb 1986 from Olivetti M24 computer. The video card is OK.

Here are some photos and a video: https://1drv.ms/u/s!AsoOXKPKfQ6FgsJarUMObkyYtrJMBw?e=9tczyo

Can I do something without changing ICs? There are some white things at the back. Is there a way to adjust the horizontal sync with them?