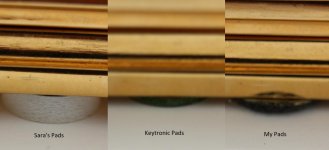

After spending some quality time with the pads, calipers, a scope, and the analog mux U19 I believe the fundamental problem is the thickness of the pads. I measured the pads at ~3.5 mm but there's variance because not all of them are perfectly flat (I believe a slight slope of the mylar/aluminum becomes important). Further, unpressed, a key's "plunger" is 8 mm from the lower edge of the key's housing (and hence, the keyboard PCB). When pressed, a key's plunger travels 5 mm, leaving 3 mm to the PCB that must be accounted for by the pad, which must then apply enough pressure to the mylar/aluminum to create enough capacitance to be detected. 0.5 mm isn't a lot of margin for error, especially for pads that aren't perfectly flat (i.e., have some slope). The visual difference between mostly working (left) and non-working (right) can be seen in the attached photo.

(A theory about a sloped pad is that while it may ultimately present enough of a capacitance change it does so in a fashion that it gets rejected as spurious by the sense amp and downstream logic. Just a thought...)

Scoping the inputs and output of the analog mux at U19 showed that as a key is depressed the magnitude of the pulses propagated to the sense amp vary significantly depending on how far the key is depressed. If the key is bottomed out you'll (of course) get maximum capacitance and a pulse the sense amp may (or may not) accept as a valid keypress. Keys with the better-acting pads (similar to the one on the left in the photo) more reliably produced detectable pulses while ones similar to the pad on the right rarely (or never) produced pulses with enough magnitude to be detected.

I think the fundamental problem is the ~3.5 mm height of the pads. They should probably be 4-4.5 mm instead. The double-height pads I tried are too tall (too stiff when their key is pressed) and sloped so I believe they end up having their keypresses rejected by the logic downstream of the sense amps.

Thoughts?

View attachment 46864