I finally had an opportunity to work with the foam pad set I ordered on eBay on Sep 27, 2018 for my Compaq Portable. Before starting the replacement, the keyboard basically had about 1/3 of the keys not working. After replacing the pads with the new ones, I kept getting "stuck key" symptoms, even after some advice from another to make sure I got the mounting plastic disc under all four tabs in the key caps. Still the same stuck key symptoms. That same person told me the pads may be too tall for the Compaq keyboard and that's why I'm getting a stuck key. I even made sure that I see no mylar surfaces sticking out of the key cap well after the pads are inserted. There appears to be less than 1/8 inch difference between the square key cap frame surface and the recessed mylar surface on the foam inserts. Does that make the gap too shallow? Could gravity simply be allowing the foam to stretch just enough to cause surface contact with the circuit board? I have verified that the space bar is at least one of the stuck keys, no matter how many times I reinsert or replace the foam insert for the space key, as the cursor moves one space at a time when DOS prompts me for a new time and date.

Someday I'll be able to find a block of time to revisit the issue. It was just a bit disappointing to go through all this and having these issues.

I am so sorry for the struggles you’re having! I know it can be a finicky process and doubt in the replacement pads does not help. I would like to send you another bag with shorter pads. The pads do vary in size a bit due to the nature of the open cell foam so I can get a bag of shorter pads for you to try if you would like. If so, please send me a message with your eBay name and actual name so I can find your old order. I will get a set out to you right away.

I also thought I would add updates as to what has happened with the testing and so forth. I am going to make it as short as I can as I plan to add much more detail in a blog post on our website. We have spoken to KeyTronic at this point as well as one of their original manufacturers so I thought the vintage computer community would appreciate the knowledge. I will likely wait until one more thing I discuss below is finished.

Since the testing on this thread fizzled, I have managed to get my hands on some old terminals that were stored in an airplane hangar for years. Needless to say, they were all a mess, so they are prime for testing. All I have done to the PCB in my terminal is cleaned it with a bit of rubbing alcohol, no eraser applied!

So now I can test on my old terminal and a my, all too reliable, Compaq Portable. I have also had many people purchase pads and come back with success stories and even get more pads for other machines. I have also had someone use them on a BTC keyboard.

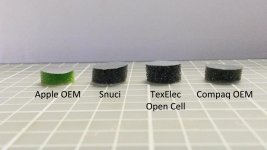

That being said, I have also had a handful of people have issues. With the exception of one other customer, the problem has been with some keys not registering a reading on key press. In some cases, this was remedied by cleaning the PCB pad repeatedly. I don’t always hear the end results so I don’t know what happened with everyone. These few issues have triggered me to keep trying, as you all know, I don’t want to give up on these pads! While I tried doubling up the foil side, we decided to give contacting KeyTronic another try. Yes, we had tried long ago to no avail. My testing led me to determine I needed thinner aluminum plated mylar which has now been verified by an analysis of the original pads by a metalizing company! In fact, my original aluminum plated mylar thickness was correct only it is 1mil “sandwiched”, not a single layer of 2mil.

I have had one other customer contact me, it was just about a week ago actually, with a similar height issue and it was on a Compaq. Note, I am not having this issue on my Compaq. Like I said, my Compaq is too reliable.

This customer decided to make shims with a 3D printer instead of getting another bag from me. It is possible you both received an extra tall batch. But I’m not really satisfied with this outcome, so we decided to try another foam manufacturer to see about getting foam custom cut elsewhere. It just so happens that the manufacturer we called knows a guy with a special machine and now I have a sample on the way right now!