Hugo Holden

Veteran Member

I have been using the Dupli-Color spray (a very old product), for metals and plastics and restoration jobs, for how long ?.......thinking back I first used it when I was about 15 years old, so about 45 years now. I have a lot of experience with it. I have some objects that I sprayed over 30 years ago still, look unchanged. The paint is not only excellent for every plastic I have used it on, it is quite UV resistant, being designed for automotive use. Indoors, it seems ageless. I cannot see any obvious need to go looking for an alternative paint and it comes in nearly every conceivable shade & clear.

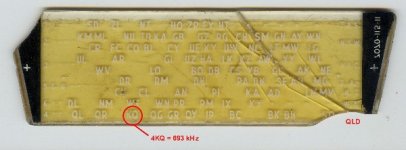

PS: the clear Dupli-color is superior on Brass to any other lacquer I have tried, very adherent, have a look at this radio with brass escutcheons that I restored over 15 years ago, they still look the same today, so the clear provides a very waterproof / moisture proof layer too:

https://www.worldphaco.com/uploads/THE_GREBE_MU-1.pdf

PS: the clear Dupli-color is superior on Brass to any other lacquer I have tried, very adherent, have a look at this radio with brass escutcheons that I restored over 15 years ago, they still look the same today, so the clear provides a very waterproof / moisture proof layer too:

https://www.worldphaco.com/uploads/THE_GREBE_MU-1.pdf

Last edited: