So I'm waiting for parts to get into the business of actually building my TVT. As mentioned, I have enough parts to build 2 or 3 of them. And there was a reason for that: I wasn't giving up completely on building a replica of the unit that actually appeared on the cover of the Sep. 1973 Radio Electronics. That was the one I really wanted to do; after all, it's the cover unit. For a refresher here it is:

You can see why they went with this one over the prototype for the shoot -- it's far more refined. Not a lot is known about it and its whereabouts today are a total mystery. I've done a lot of reading and have not found anything to indicate whether it was fully functional. I'm still reading, hoping to find it in another article, as RE frequently revisited past projects to update or change things. The basic case structure looks simple enough -- plywood sides and what I think is painted metal of some kind (I think, maybe other eyes can tell?). Judging by the location of the switches, it appears the actual TVT boards are mounted directly under the keyboard, rather than behind it as in the prototype. Although it's possible the switches weren't soldered directly to the board as they were supposed to be.

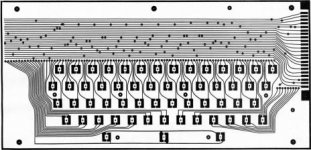

Now, there's some problems with this from a replicator's standpoint. One, there's only this one photograph of the unit. I've not found another picture taken of it, from another angle or anything. Since the unit's whereabouts are unknown, I can't ask someone for measurements as with the prototype. A lot will have to be inferred from the single photograph of the complete unit, and an extra, super grainy photo of the keyboard, which was its own project some months before:

As a railway modeller, I can handle all that. I'm used to working with next to no information and not being able to get real-world measurements. However the showstopper with this thing, until now, was the keytops. In the parts list from the 'low cost keyboards' article, a company called Mechanical Enterprises could be called upon to produce the keytops shown therein. I've searched on and off for 6 years without success in finding any. I assumed it was a lost cause and that's why I went to building the prototype, buying enough parts to do a couple of TVTs 'just in case'.

Anyway, one day last week I'm sitting around playing with my CT-1024 when I notice something. The keys on my terminal look just like the ones on the cover unit. I check and re-check a few times.. and sure enough.. it appears they are! Same concave keytops, square base, same height all around. The space bar, like the cover unit, is curved at the top. The one in the photo looks to be equal height on all sides, whereas mine is longer on the end facing the user. But I think that's just a trick of the photo. Given the relationship between SWTPC and RE at that time, it's not unreasonable to think they were getting their keys from the same places.

I also noticed on close inspection that the lettering on my SWTPC keyboard was painted on, not engraved. Reading the low cost keyboards article, Don made mention of being able to order the keytops with any 'reasonable callouts' on them. So there was a good likelihood that was why I couldn't find any keys like the ones on that unit: they were custom made for that project. And in fact, if you look at the photos, you can see one or two 'booboos' where the callouts/legends are not aligned properly with the others (ie the letters are too low). So, we're back to the realm of possibility here, since I have experience making rubber molds and being able to cast parts. What I realized I could do was 'borrow' the space bar and a few of the blank keys on my terminal and make a mold of them.

Now, I don't have the skill to cast a part that complex exactly. What I'll end up with is a 'keytop' that is a solid block rather than a cap. But that's okay. The low cost keyboard design provides some flexibility. I can use a drill press and drill out the backside of the keys to a certain degree. Anyway, after the mold dried I did a couple of test castings:

So, it's quite possible. I would have to paint the finished product, since it's not injection moulded plastic. But I think I can make it convincing. The lettering I'm guess will have to happen via silkscreen, and there's going to be some guesswork as to what some of the extra symbols were. But getting the actual keytops was really the worst of it. Now that I have a way to create those.. I can start thinking seriously about what materials I need to do the rest.