My high school had to kick the old stuff sometime, but I didn't think of it when I was supposed to, only recently...

I'd really like to recover a good old 100-200 MHz scope, digital ones aren't cheap at all.

The scope I would recommend is the Tek 464 (or 466). These are fantastic, I have three of them (I went nuts over them) They can store for very long periods and its easy to photograph the display. In non storage mode they are a beautiful performer, so its better to have the ability to store in the scope, even if you don't use it much. The construction quality is unmatched by any modern scope.

The thing is, and here is what most don't know, certainly ebay sellers don't appear to be aware of it at all:

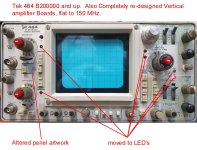

The truth of it is not in clearly stated in the manuals either (there are two different service manuals), unless you can read between the lines and inspect the scope's interior and test them out with leveled sine wave generators. After serial number B200000 and up, Tek make a massive upgrade to the 464 scope, though curiously did not change its manual specs or its model number. Though in the later manual it did say the vertical amplifiers were 100MHz..or better.

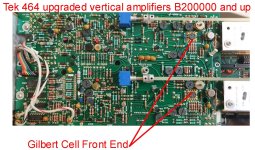

Tek completely re-designed the Vertical amplifiers and went to a Gilbert Cell front end, in a custom Tek chip. (this had large advantages including a very easy invert for channel 2). Also they upgraded to panel LED's and altered the front panel artwork making the scope change easy to recognize externally at a distance, but still is was said to be a 464 model scope.

(compare the photo I have attached to many other 464 scope images on the net)

Now the manual specs in both manuals say the 464 is a 100 MHz scope implying, perhaps, that its vertical amplifiers are -3dB down at 100MHz. While I don't have the earlier 464 versions to check (I insisted on the updated versions for myself), I can promise you that the late model 464 is perfectly flat to 150MHz and only -3dB down at 160 MHz. I have Tek leveled sine wave generators to test & calibrate them.

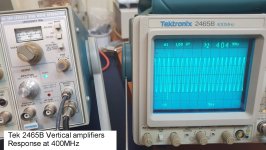

And here is another surprise; the Tek 2465B is a 400MHz rated scope. But Tek could have marketed it as a 650MHz one. Because it is flat to well over 400MHz and only -3dB down at 650MHz and 6dB down at 760MHz, it is astonishing. Mind you my scopes are all in perfect calibration. I have attached 5 test images

Also, though I don't have one to check, but apparently some time in the past I read that an ebay seller/repairer found this out; the 2465A that was rated by Tek as a 350MHz scope was actually flat to over 400MHz on testing, so the seller started to re-badge the 2465A's as 2465B's because he had 2465B badges. He said that Tek made an error and he found them out. Still I didn't like that much because the two scopes were a little different inside and I don't think the bandwidth of the A model was as good as the B, and passing one off as the other is not ethical. Also accusing Tek of making a mistake, well that is bordering on Blasphemy, because to me at least, Tek were the Gods of scopes who always, historically at least, delivered more than they promised.

So it seems in the old days, Tek and Telequipment, both significantly under-rated the bandwidth capabilities of the vertical amplifiers in their scopes. That sort of under-spec-ing doesn't happen any more.

In any case, I suggest that you get the late version of the Tek 464 (like the one in the attached photo, you will fall in love with it and never sell it). I wrote an article on these to help calibrate them: