Hugo Holden

Veteran Member

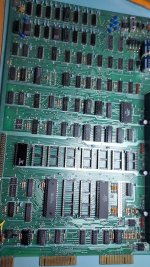

Probably not a solder bridge as its too thin and uniform, but it could be one of two things: Some man made lint, in which case it would be an insulator. Or it could be a dreaded Tin Whisker ! It would be worth checking between those pins with the meter.

One of the more difficult faults I ever tackled was a Tin whisker in one of my beloved 2465B scopes. It took me a week to find the problem. It developed an intermittent problem where the beam would randomly deflect downwards. There was a section on the main board (on the inaccessible surface of course) that had the whisker where there was no track coating. It is a lot of work to take that board out. I wrote up the story. Not long after I found out about a stack of main boards at a Tek scope repairer, that were deemed "unrepairable" and I'm sure these would have had the same problem.

On another occasion, one of my more modern LG workshop VDU's suddenly started acting as though somebody was intermittently pressing the menu button (like a Ghost in the machine). And at the same time the screen image changed contrast on exactly one half of the screen. But this time the penny dropped early, because two completely different parts of the circuit malfunctioned at once (that is a very big Tin Whisker clue). It was also a board proudly boasting "Pb Free" (thank God this is not allowed in Avionics).The Greens might pay to learn that the road to Hell is paved with good intentions. A whisker was linking two pins on a fine pitch pin processor IC. When I washed and scrubbed the board, the problem was much more extensive, a grey slurry of fine shorter whiskers came away from the surfaces, so many more faults were about to occur.

One of the more difficult faults I ever tackled was a Tin whisker in one of my beloved 2465B scopes. It took me a week to find the problem. It developed an intermittent problem where the beam would randomly deflect downwards. There was a section on the main board (on the inaccessible surface of course) that had the whisker where there was no track coating. It is a lot of work to take that board out. I wrote up the story. Not long after I found out about a stack of main boards at a Tek scope repairer, that were deemed "unrepairable" and I'm sure these would have had the same problem.

On another occasion, one of my more modern LG workshop VDU's suddenly started acting as though somebody was intermittently pressing the menu button (like a Ghost in the machine). And at the same time the screen image changed contrast on exactly one half of the screen. But this time the penny dropped early, because two completely different parts of the circuit malfunctioned at once (that is a very big Tin Whisker clue). It was also a board proudly boasting "Pb Free" (thank God this is not allowed in Avionics).The Greens might pay to learn that the road to Hell is paved with good intentions. A whisker was linking two pins on a fine pitch pin processor IC. When I washed and scrubbed the board, the problem was much more extensive, a grey slurry of fine shorter whiskers came away from the surfaces, so many more faults were about to occur.

Last edited: