Hugo Holden

Veteran Member

Well this explains why the raster is so bright.For exactly it's 8.1 volts on all three

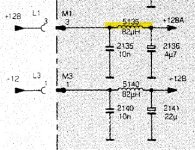

The video amplifiers are composed of a direct coupled transistor circuit for each channel, fed by a signal processor IC TDA3505(7640). The transistor pairs are configured in the Cascode arrangement, a clever invention to eliminate the effect of the Miller capacitance of the input transistor, by pinning its collector voltage to a fixed potential.

Most likely the transistor stages are ok, if the supply voltages to them are normal. Whatever the cause is, it is affecting the three channels equally.

The output of the IC are pins 5,3 and 1 each should have 3.6V on them. If not, something is upsetting the DC conditions of the IC, equally for the three channels. Check the IC's power supply on its pin 6, it should be 11.3V

The variable DC levels from the contrast and brightness controls are introduced to the IC at pin 20 , should be 1V (brightness) and on pin 19, 2V (contrast).

Last edited: