Dwight Elvey

Veteran Member

This is always an issue. The fact that you have replaced the CPU, indicates that you or someone before you has desoldered the original CPU.

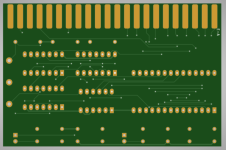

The boards these were made from were really cheap. Before doing anything else, run through with an ohm meter for each pin, top and bottom. I'm an experienced person with a soldering iron. I had to repair one trace on my board so expect to check them all.

Are any of the other chips on sockets? The same thing. They need to be checked. To my knowledge, no KIM-1 ever had sockets from the factory.

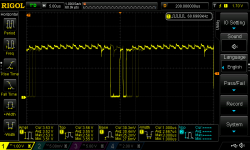

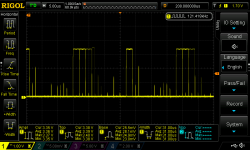

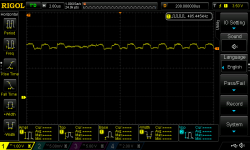

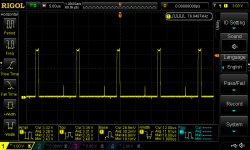

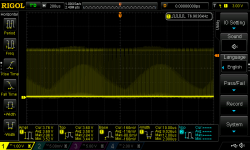

If that is all ok, we need to go to a meter or a scope.

Check that things that Dave has listed.

The board has a mixture of TTL and MOS inputs. An open TTL input is a soft pull up of about 2.5 to 3 volts on a meter.

Since I assume the CPU is socketed, lets start by pulling it. The first test only needs the processor running, a working address buss, data bus and no extra things like interrupts going in.

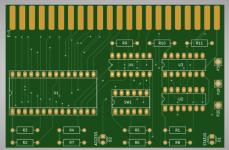

I assume you have a schematic to look at ( http://www.zimmers.net/anonftp/pub/cbm/schematics/kim-1/kim.gif works well enough.

The debug board must be the boot code. This means the jumper need to make the KIM-1 work without the debug board, needs to be disconnected.

That is, no jumper tie on pin K. That is replaced with the switch labeled DB.

With the CPU removed check the pin on the address decoder, U4, inputs, 12, 13, 14, 15. They should all be "1". I will call any thing of 2or more volts a "1".

Now do the same for U4's outputs, pins 1 to 7 are "1". Pin 9 should change with the DB switch on the debug board. When "1" the debug board take over the

source of the boot code.

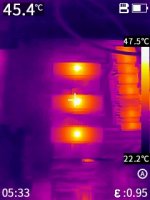

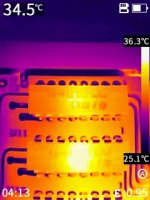

After things have been powered with the CPU removed for a while, do a temperature check of all the parts, nothing should be particularly hot.

Once past that, we can look at other things. As I recall, the Debug board doesn't need much other than a working address bus and data bus to do the first test.

Also, note that the switches on the debug board are not in a friendly order. Don't use the switches position numbers, note the schematic.

The boards these were made from were really cheap. Before doing anything else, run through with an ohm meter for each pin, top and bottom. I'm an experienced person with a soldering iron. I had to repair one trace on my board so expect to check them all.

Are any of the other chips on sockets? The same thing. They need to be checked. To my knowledge, no KIM-1 ever had sockets from the factory.

If that is all ok, we need to go to a meter or a scope.

Check that things that Dave has listed.

The board has a mixture of TTL and MOS inputs. An open TTL input is a soft pull up of about 2.5 to 3 volts on a meter.

Since I assume the CPU is socketed, lets start by pulling it. The first test only needs the processor running, a working address buss, data bus and no extra things like interrupts going in.

I assume you have a schematic to look at ( http://www.zimmers.net/anonftp/pub/cbm/schematics/kim-1/kim.gif works well enough.

The debug board must be the boot code. This means the jumper need to make the KIM-1 work without the debug board, needs to be disconnected.

That is, no jumper tie on pin K. That is replaced with the switch labeled DB.

With the CPU removed check the pin on the address decoder, U4, inputs, 12, 13, 14, 15. They should all be "1". I will call any thing of 2or more volts a "1".

Now do the same for U4's outputs, pins 1 to 7 are "1". Pin 9 should change with the DB switch on the debug board. When "1" the debug board take over the

source of the boot code.

After things have been powered with the CPU removed for a while, do a temperature check of all the parts, nothing should be particularly hot.

Once past that, we can look at other things. As I recall, the Debug board doesn't need much other than a working address bus and data bus to do the first test.

Also, note that the switches on the debug board are not in a friendly order. Don't use the switches position numbers, note the schematic.