razza

Member

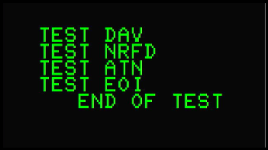

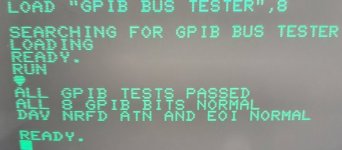

I bought an SD2PET a couple of weeks back and it's been fine for the few hours I have used it. When I execute CATALOG from the machine locks. If I use LOAD "$",8 it just searches. When the machine boots, the LED on the SD2PET is not illuminated. After the CATALOG command is executed, the LED goes green. I am assuming the SD2PET is functioning.

Daver2 shared a link to a book entitled PET and the IEEE 488 Bus (GPIB) by Fisher, E. R. (Eugene Ralph), 1940-; Jensen, C. W. (C. William), I have not yet looked at this.

I have read this thread Commodore PET restoration help needed and I have mostly replicated the testing found in post 144 which I think is taken from the table in the Tynemouth Blog. I have not tested the voltages on the IEEE interface yet.

For those who understand how this interface works, does anything look awry in the following results?

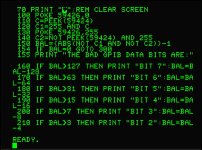

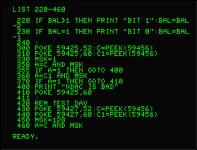

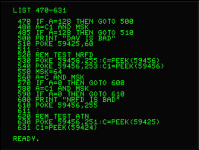

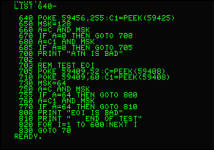

DIO1-8: Starting value 255

POKE 59426,0. PRINT PEEK(59424) value of 0.

POKE 59426,255. PRINT PEEK(59424) value 255.

EOI: Starting value 249

POKE 59409,52. PRINT PEEK(59408) value of 185.

POKE 59409,60. PRINT PEEK(59408) value 249.

DAV: Starting value 189

POKE 59427,52. PRINT PEEK(59456) value of 61.

POKE 59427,60, PRINT PEEK(59456) value of 189.

NFRD: Starting value 189

POKE 59456,253. PRINT PEEK(59456) value of 189.

POKE 59456,255. PRINT PEEK(59456) value 255.

NDAC: Starting value 255

POKE 59425,52. PRINT PEEK(59456) value of 254.

POKE 59425,60. PRINT PEEK(59456) value 255.

ATN: Starting value 60

POKE 59456,251. PRINT PEEK((59425) value of 188.

POKE 59456,255. PRINT PEEK((59425) value of 188.

Daver2 shared a link to a book entitled PET and the IEEE 488 Bus (GPIB) by Fisher, E. R. (Eugene Ralph), 1940-; Jensen, C. W. (C. William), I have not yet looked at this.

I have read this thread Commodore PET restoration help needed and I have mostly replicated the testing found in post 144 which I think is taken from the table in the Tynemouth Blog. I have not tested the voltages on the IEEE interface yet.

For those who understand how this interface works, does anything look awry in the following results?

DIO1-8: Starting value 255

POKE 59426,0. PRINT PEEK(59424) value of 0.

POKE 59426,255. PRINT PEEK(59424) value 255.

EOI: Starting value 249

POKE 59409,52. PRINT PEEK(59408) value of 185.

POKE 59409,60. PRINT PEEK(59408) value 249.

DAV: Starting value 189

POKE 59427,52. PRINT PEEK(59456) value of 61.

POKE 59427,60, PRINT PEEK(59456) value of 189.

NFRD: Starting value 189

POKE 59456,253. PRINT PEEK(59456) value of 189.

POKE 59456,255. PRINT PEEK(59456) value 255.

NDAC: Starting value 255

POKE 59425,52. PRINT PEEK(59456) value of 254.

POKE 59425,60. PRINT PEEK(59456) value 255.

ATN: Starting value 60

POKE 59456,251. PRINT PEEK((59425) value of 188.

POKE 59456,255. PRINT PEEK((59425) value of 188.

Last edited: