Hey everyone!

Chicklet 2001's are super rare in my neck of the woods (South Africa) and, after many years of searching, I eventually found one.

I've repaired many a vintage computer, including a bunch of 8032s (with the help and guidance of the two Daves, and the likes of Mr. Holden, on this forum), but have never worked on a 2001. So hoping for a few tips and best practices to quickly point me where to start. I've read a number of threads, on this forum on similar repairs, such as this one. I'm relatively OK reading circuits and using test kit.

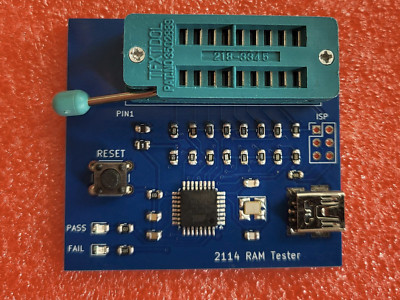

The board is marked as both a 320137 and 320136E and is a 2114 board. There are only 4 ROMs on the board.

The whole system have a huge amount of rust and a number of pins on the ROMs have rusted off. The Character ROM seems fine though and I can verify it in my EPROM reader.

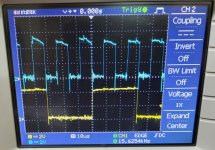

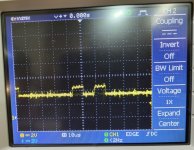

Voltages (all 4), clock and reset are all good.

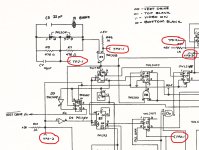

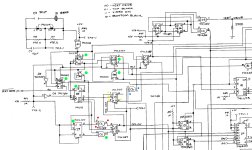

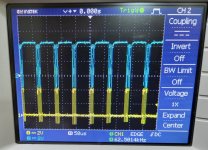

My understanding is that the 2001 should put out video signals, independent of the CPU side working properly. I'm not seeing this. H, V and Video show DC levels, so I thought I'd first start here.

Some questions, please:

- Is this correct? Can I assume that the video circuit should work independently of the "CPU" and I should get that working first? At least getting H- and V-sync signals before worrying about the CPU-side of things? (I did put in a RAM/ROM replacement board for a quick test but it did not make a difference).

- If so, are there a couple of obvious places to start / test? I've not yet done any tracing down the H/V sync paths.

- The IO chips look worse for wear, are they needed for the video circuit (like on the 8032) or can I safely ignore them / remove them from the board?

- Is there a service / repair manual for the 2001? I've searched quite a bit, but could not find one.....

Any help / tips / best practices / etc. will be really cool.

Chicklet 2001's are super rare in my neck of the woods (South Africa) and, after many years of searching, I eventually found one.

I've repaired many a vintage computer, including a bunch of 8032s (with the help and guidance of the two Daves, and the likes of Mr. Holden, on this forum), but have never worked on a 2001. So hoping for a few tips and best practices to quickly point me where to start. I've read a number of threads, on this forum on similar repairs, such as this one. I'm relatively OK reading circuits and using test kit.

The board is marked as both a 320137 and 320136E and is a 2114 board. There are only 4 ROMs on the board.

The whole system have a huge amount of rust and a number of pins on the ROMs have rusted off. The Character ROM seems fine though and I can verify it in my EPROM reader.

Voltages (all 4), clock and reset are all good.

My understanding is that the 2001 should put out video signals, independent of the CPU side working properly. I'm not seeing this. H, V and Video show DC levels, so I thought I'd first start here.

Some questions, please:

- Is this correct? Can I assume that the video circuit should work independently of the "CPU" and I should get that working first? At least getting H- and V-sync signals before worrying about the CPU-side of things? (I did put in a RAM/ROM replacement board for a quick test but it did not make a difference).

- If so, are there a couple of obvious places to start / test? I've not yet done any tracing down the H/V sync paths.

- The IO chips look worse for wear, are they needed for the video circuit (like on the 8032) or can I safely ignore them / remove them from the board?

- Is there a service / repair manual for the 2001? I've searched quite a bit, but could not find one.....

Any help / tips / best practices / etc. will be really cool.