NeXT

Veteran Member

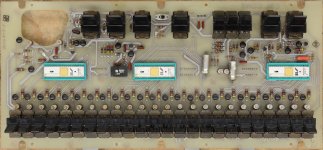

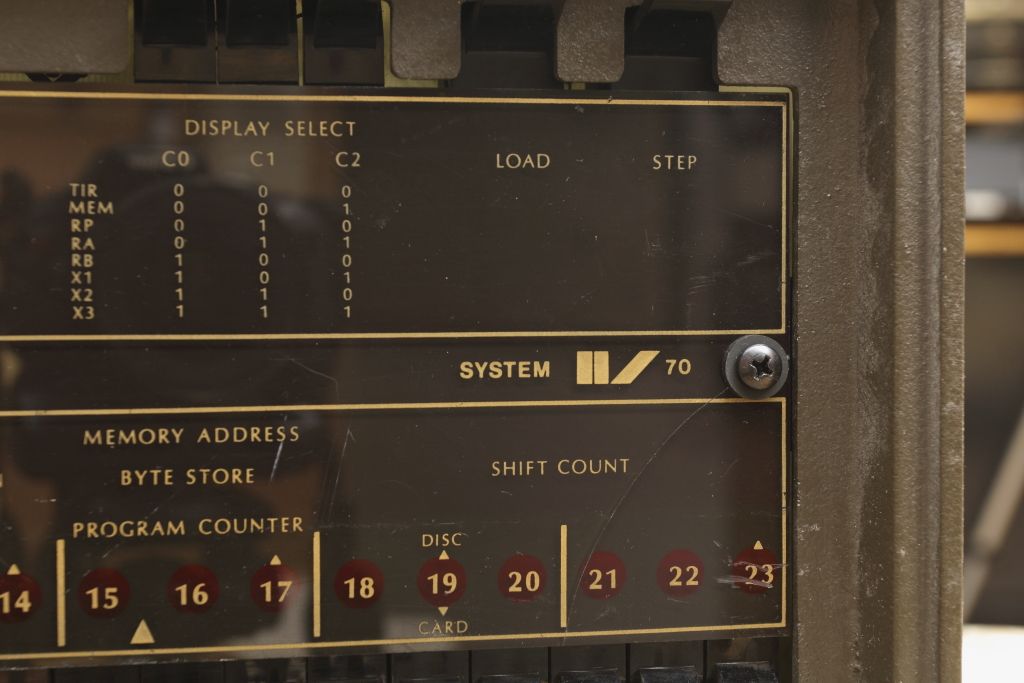

While talking to the local Four-Phase guy about the issue of 2N3643's going pop he asked I go over the power supply again suspecting either one of the rails have gone out of tolerance or there's a considerable amount of ripple. I mentioned I had already checked this but he said to go through it again and more importantly, load and adjust the voltage rails to spec. I'll need to talk to him regarding if I should load and adjust each rail one at a time or load them all at once and adjust them. As you can see on the first page there are multiple adjustment pots underneath but on my first pass beyond making sure the rails were in tolerance I didn't dare touch them so he'll be helping me double check them next time I'm on the coast.

I also determined the replacement nylatch bits are available, however there's a large catalog of both pull pins and the part that remains captive in the part. A few pieces I found around here were the wrong sizes. I tried plastic captive panel screws for stuff like car dashes and found they were not sufficient.

Quotation also came back to make a replacement aluminum cover for the top. A single sheet with two bends and four screw holes is. $300.

I'll be looking for other sheet metal services....

I also determined the replacement nylatch bits are available, however there's a large catalog of both pull pins and the part that remains captive in the part. A few pieces I found around here were the wrong sizes. I tried plastic captive panel screws for stuff like car dashes and found they were not sufficient.

Quotation also came back to make a replacement aluminum cover for the top. A single sheet with two bends and four screw holes is. $300.

I'll be looking for other sheet metal services....

Last edited: