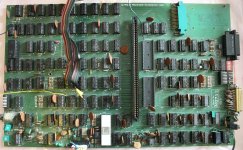

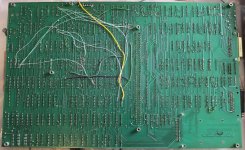

A photo of the board is perfectly good to make a replica pcb, I did this with photos, from the internet of the pcb for the Votrax Type 'N Talk unit: have a look at the board in this article:

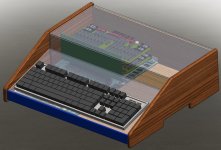

When I finally got an original Votrax pcb, my replica had turned out practically identical. I also hunted down the correct connectors, switch, period correct axial ceramic capacitors, the Xtal and everything else required to make a proper replica of the original board. This sort of thing increases the probability of everything working first time, which it did. The study of it also found that the manufacturers had inadvertently left out a small section of track work, but the original units worked anyway as luck would have it. It requires a lot of attention to detail to make an accurate replica.

Three things help here:

One is that if the camera angle is off perpendicular with the board surface (as often is the case with a flash photo to avoid reflections) there is a function in photo studio that can correct for that and convert it into what would be a square on image.

One other thing, because of the known IC sizes and pin spacing and known some other component geometry, it sets the scale of the whole board.

Also, I have found that most of the pcb's of this era, the designers tended to lay IC's and component holes over a 2.54mm (1/10") grid and place the vias (often but not always) on those or at regular positions in between those. I reconstruct the pcb pads/holes over the grid as a transparency and remove the grid later.

Obviously, a scan is better and saves some time creating a replica, but it is not always available. It also helps to have the schematic at a minimum (or the real original board) to determine the tracks hiding under the IC's, for the Type 'N Talk unit I resolved those from the schematics.